Semi-automatic ointment filling machine

◆ Semi-automatic Ointment Filling Machine Introduction

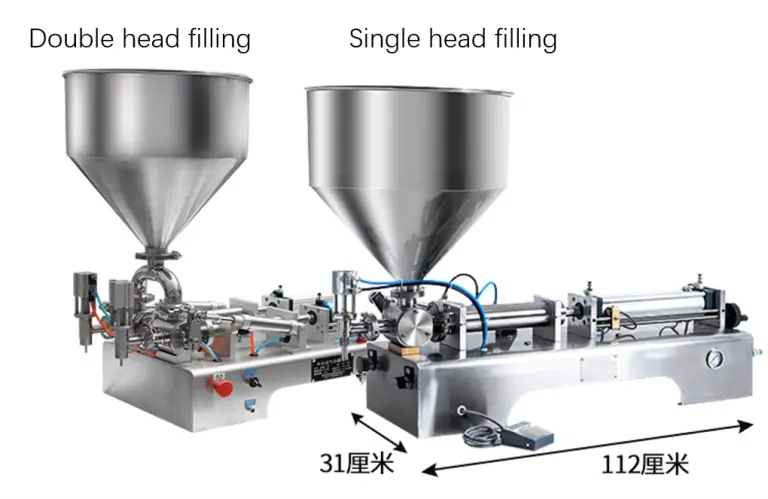

This semi-automatic ointment filling machine is available in single-head and double-head models, which are suitable for filling ointments in the daily chemical, pharmaceutical, food, ink, and paint industries.

◆ Principle and Features:

● This ointment filling machine is designed for filling products with medium to high viscosity.

● The machine consists of a material hopper and an electrical control system, with a simple structure and easy operation.

● Both the filling quantity and speed are adjustable, with high filling accuracy.

● The filling head adopts an anti-dripping and anti-drawing filling device.

● This machine can be modified into an explosion-proof filling system according to customer needs.

◆ Technical Parameters

| Product name | Semi-automatic ointment filling machine |

|---|---|

| Model No.: | YS-1000 |

| Machine Type: | Filling Machine |

| Applicable Industries: | Food & Beverage Factory, Restaurant, Home Use, Food Shop, Other, |

| Application: | Food, Beverage, Commodity |

| Packaging Type: | CANS, Bottles, Bags, Pouch, Other |

| Packaging Material: | Plastic, Metal, Glass |

| Filling Material: | Honey, Milk, Water, Oil, Juice and so on. |

| Hopper capacity: | 30L |

| Filling range: | 80-1100ml |

| Optimal Filling range: | 100-1000ml |

| Optional Filling range: | 10-100ml; 30-300ml; 50-500ml; 100-1000ml;300-3000ml,1000-5000ml, etc. |

| Filling Accuracy: | ±1% |

| Automatic Grade: | Semi-automatic |

| Driven Type: | Pneumatic and electric |

| Rated Air Pressure: | 0.4-0.6MPa |

| Voltage: | 220V/110V 50Hz/60Hz |

| Power: | 10W |

| Dimension(L*W*H): | 113*32*30cm |

| Weight: | 27.6 KG |

◆ Details and Advantages of Filling Machine

-

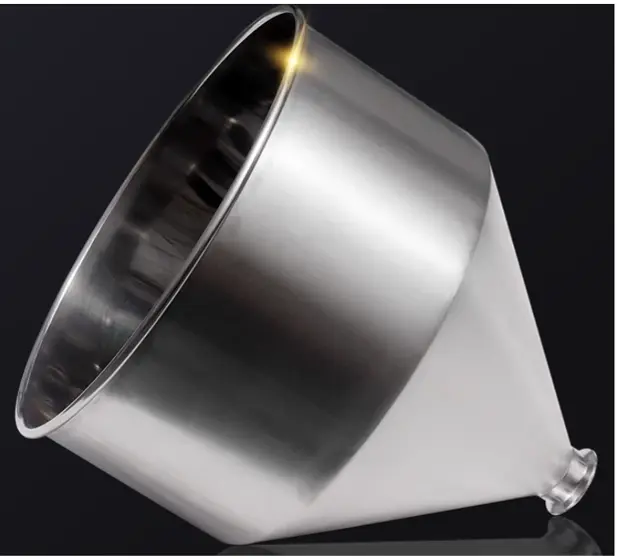

• Food-grade Materials;

Big stainless steel hopper, and the metal that comes into contact with the liquid or ointment to be filled are made of 304 stainless steel, which has corrosion-resistant, wear-resistant, safe and healthy characteristics. -

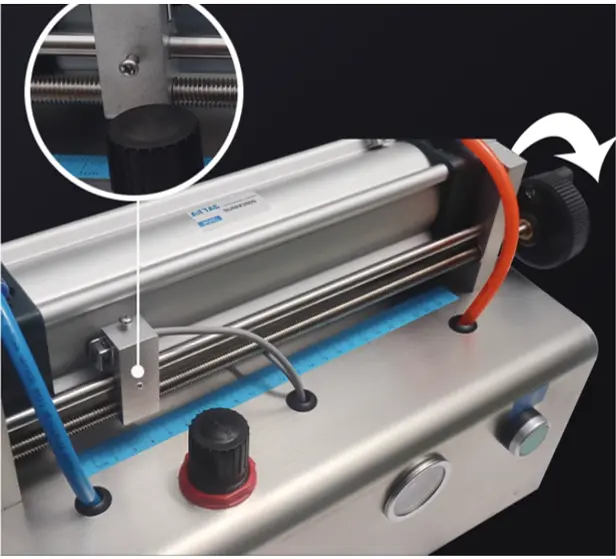

• Convenient Adjustment of Filling Volume;

High-quality cylinder with good sealing, stable and corrosion-resistant air pressure, can accurately control every filling, ensuring accurate measurement.

-

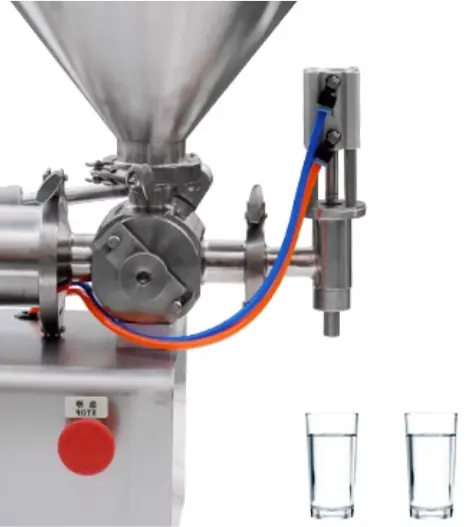

• Stainless Steel Discharge Nozzle;

Made of high-quality steel, stable and durable, with accurate filling performance and long service life, equipped with a high-precision anti-drip filling system. -

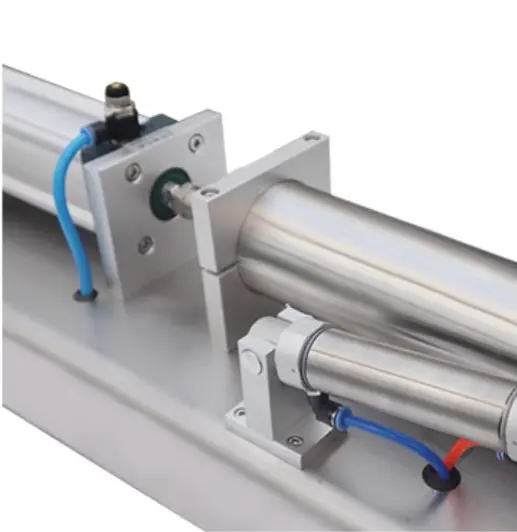

• High-quality Piston;

Equipped with a PTFE piston, which is wear-resistant, has good sealing performance, and is durable

-

• Filling Adjustment Lever; Rotates to adjust the filling amount, allowing for easy adjustment of the quantity, and convenient operation

-

• Emergency Stop Switch;

An emergency stop button that can immediately stop the machine's operation.

• Manual/Automatic mode, Rotary switch;

Filling jog mode: Equipped with a foot switch, press once to discharge once; Automatic mode: Interval time can be set, allowing for complete control over the filling process.

◆ urange of applications

This filling machine has a wide range of applications, suitable for filling liquids and pastes, suitable for filling a variety of products with accurate measurement.

◆ Warmy Reminder:

This semi-automatic filling machine needs to be used with an air compressor, the equipment does not include an air compressor. It needs to be extra purchased by the customer.

+86 19112905173

+86 19112905173