powder packing machine working principle and precautions for use

Fully automatic powder packing machine can be used for automatic bag packaging, sealing, packaging, cutting, and other processes of powdered materials. According to hygiene regulations, manual packaging is not allowed for food and pharmaceutical products to avoid contaminating the products, and successfully avoids direct contact between human hands and the materials, ensuring hygiene and quality. In addition, using the can also avoid and reduce environmental pollution caused by powdered materials and minimize potential health damage to the pouch packing machine operator. Therefore, it has been favored by numerous manufacturers of powdered materials. This article introduces the powder packing machine working principle and its application in daily life.

◆ powder packing machine working principle

To explain the powder packing machine working principle, it is necessary to first understand the metering methods used by the powder packing machine. Based on different metering methods, the working principle can be specifically explained.

From the perspective of quantitative principles, the powder filling and packing machine mainly has two methods: volumetric and weighing.

(1) Volumetric

This refers to the method of quantitative filling by controlling the volume of the filled material, and the screw-type powder filling and packing machine belongs to the volumetric quantitative filling. The advantages of this type of powder filling and packing machine are its simple structure, no need for weighing devices, low pouch packing machine cost, and high filling efficiency. However, the accuracy of filling varies greatly depending on the characteristics of the filled material, such as stability of specific gravity, uniformity of particle size, moisture absorption, and looseness. Therefore, volumetric powder packing machines are mainly suitable for materials with uniform particle size, stable bulk density, and good self-flowing properties.

Volumetric quantitative filling can be divided into two forms based on the different material measuring methods:

● The first is to control the filling volume by controlling the flow rate or time of the material, such as controlling the volume of the filled material by controlling the rotation cycles or time of the screw, control the volume of the material by controlling the vibration time of the feeder, etc.

● The second is to achieve quantitative filling by measuring the material with the same measuring container, such as using graduated cylinder, measuring cup or plunger-type quantitative filling machine, etc.

Both of these filling methods have a common issue, which is to ensure the stability of the bulk density of the filled material. In order to achieve this requirement, methods such as vibration, stirring, nitrogen filling, or vacuum pumping are often used. If high filling accuracy is required, automatic detection devices need to be used to continuously detect the changes in the specific gravity of the filled materials and make adjustments continuously to ensure the accuracy of the filling volume.

(2) Weighing

Weighing-type quantitative filling controls the accuracy of filling by controlling the weight of the filled material. Compared with volume-type filling, it has a more complex structure, higher pouch packing machine cost and lower filling efficiency. The filling object is mainly materials with uneven particle size, unstable bulk density, and relatively high price. There are currently three types of scales used for weighing-type quantitative filling, which are mechanical lever scales, electronic scales, and mechanical-electronic combination scales. According to the different feeding methods, it can be divided into single-stage feeding and multi-stage feeding. In order to improve the accuracy of quantification and feeding speed, multi-stage feeding is generally used, and dynamic weighing is performed while feeding.

◆ Application precautions of powder bag packing machine

1. Before each use, it is necessary to observe whether the surroundings of the weighing powder packing machine are normal.

2. Do not touch the operating pouch packing machine parts with your body, hands and head during operation.

3. Do not put your hands and tools into the seal holder to avoid injury during operation.

4. During normal use of the powder packing machine, the operation buttons should not be switched frequently, and the parameter settings should not be changed arbitrarily.

5. When the powder packing machine is running at high speed, it is not recommended to operate it for too long.

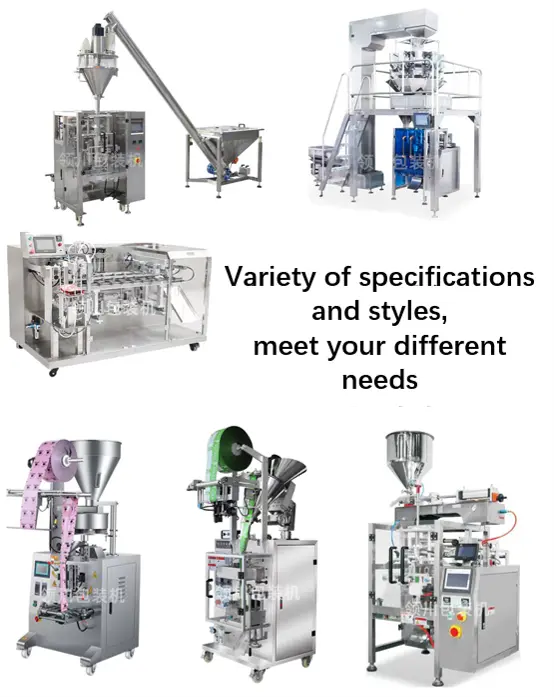

There are many types of powdered products, which can involve multiple industries such as industry, food, and agricultural products. Therefore, the powder packing machine has a very wide range of applications and is often used as a food powder packaging machine, spice powder packing machine, powder drink packaging machine, collagen powder packing machine, herbs powder packing machine, auto washing powder packing machine etc. Using a powder bag packing machine for packaging can not only avoid environmental pollution and harm to the human body caused by dust materials but also effectively improve packaging efficiency, reduce material waste, and save labor costs. It is a great helper for manufacturers of powdered materials in terms of packaging.

+86 19112905173

+86 19112905173