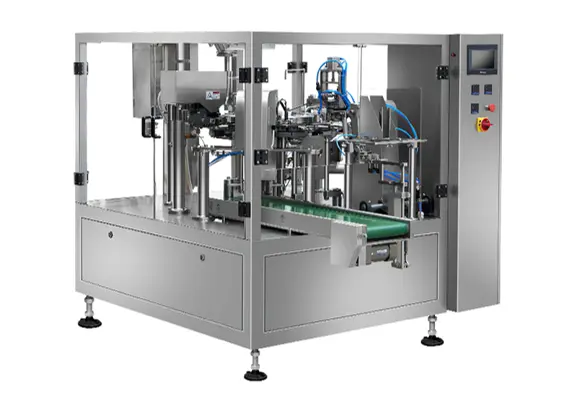

Maintenance of Automatic Pouch Packing Machine and its Application in Food Industry

◆ Classification of automatic pouch packing machine

The automatic pouch packing machine can be divided into fully automatic pouch packing machine and semi automatic pouch packing machine according to the degree of automation.

The fully automatic pouch packing machine can usually continuously complete a series of packing processes such as bag making, metering, filling, sealing, coding, and finished product output. However, due to the influence of the metering mechanism or bag-making structure, the general measuring range of the fully automatic pouch packing machine is limited, and it is usually used in occasions where the materials and packaging specifications are not frequently changed.

The semi automatic pouch packing machine generally only complete one or a few of the packing processes, but it is more flexible to use, basically does not need mechanical adjustment when changing materials or changing product varieties and specifications, and the semi automatic pouch packing machine price is cheaper than the fully automatic pouch packing machine price.

◆ Maintenance of automatic pouch packing machine

In the normal production process, machine maintainer should strictly perform various maintenance tasks of the automatic pouch packing machine within the specified period according to the maintenance manual and procedures, to reduce the wear speed of pouch packing machine parts, and eliminate the hidden danger of failure, thereby extending the service life of the machine.

What maintenances are required for a automatic pouch packing machine? The key points are: cleaning, fastening, adjustment, lubrication, and anti-corrosion. It is roughly divided into: routine maintenance, regular maintenance (including first-level maintenance, second-level maintenance, and third-level maintenance), and special maintenance (including seasonal maintenance and shutdown maintenance).

1. Routine maintenance

Routine maintenance is centered on cleaning, lubrication, inspection and fastening, and must be carried out as required during and after the operation of the small automatic pouch packing machine.

2. Regular maintenance

● First-level maintenance work is carried out on the basis of routine maintenance, and the key tasks are lubrication, fastening, inspection of relevant parts, and cleaning.

● Second-level maintenance work focuses on inspection and adjustment, specifically to check the engine, clutch, transmission, transmission components, steering, and braking components of the automatic pouch packing machine.

● Third-level maintenance is focus on detect, adjust, and eliminate potential faults and balance the wear of various components. It is necessary to diagnose and inspect the parts that affect the equipment's performance and those that show signs of malfunction, and then complete the necessary replacement, adjustment, and troubleshooting work.

3. Seasonal maintenance.

Seasonal maintenance refers to the detection and repair of automatic stand up pouch packing machine components such as the combustion system, hydraulic system, cooling system and starting system before summer and winter each year.

4. Out of service maintenance

Out of service maintenance means that when the automatic packaging machine needs to be out of service for a period of time due to seasonal factors (such as the winter break), cleaning, cosmetic surgery, matching, and anti-corrosion work should be done.

The above are the maintenance works for pouch packing machine automatic. When using the machine, we must also do a good job of maintenance and upkeep to ensure its proper use.

◆ Application of pouch packing machine automatic in the field of food

The automatic pouch packing machine is a typical electromechanical integrated product that is widely used for food packaging.

1. It can be used as an automatic tea pouch packing machine for packaging tea. There is an increasing demand for complete equipment for processing and packaging beverages that are used for brewing, represented by tea and lemon slices.

2. It can be used as automatic spice pouch packing machine and automatic masala pouch packing machine. In various cities in India, seasonings are daily necessities for people. The powder pouch automatic packing machine effectively avoids the problems of manual packaging of seasonings being unhygienic and wasting raw materials. It is created a huge consumer market in automatic pouch packing machine manufacturer india.

3. It can be used as automatic milk pouch packing machine or automatic water pouch packing machine. At present, there are countless milk factories and drinking water factories both domestically and internationally. The manufacturers in underdeveloped countries need to save costs while maintaining the cleanliness of beverages. They require not only a cost-effective automatic liquid pouch packing machine but also stable quality and attentive after-sales service. And the automatic pouch packing machine for milk and for water from China is the best choice for them.

You can visit our website to learn more about the application of automatic pouch packing machine, or read our blog to gain more knowledge about pouch packing machines. If your automatic pouch packing machine breaks down, please feel free to contact us for help, we are willing to offer you a free analysis of the cause of the failure and find solutions for you.

+86 19112905173

+86 19112905173