Factors affecting Powder Packaging Machine Efficiency and accuracy

The powder packing machine is a device for quantitatively packaging powder products in small doses. The packaging specifications provided by powder packing machine manufacturers are generally controlled within the range of 5g-5000g, and it is suitable for automatic packaging of small bags of powders or granular materials that are not easy to flow.

The fully automatic powder packing machine can automatically complete the tasks of measurement, filling, sealing, and cutting. It is widely used in many industries such as industrial, food, and agricultural products, involving various products such as milk powder, starch, pesticides, veterinary drugs, premixes, additives, seasonings, feed, and enzyme preparations.

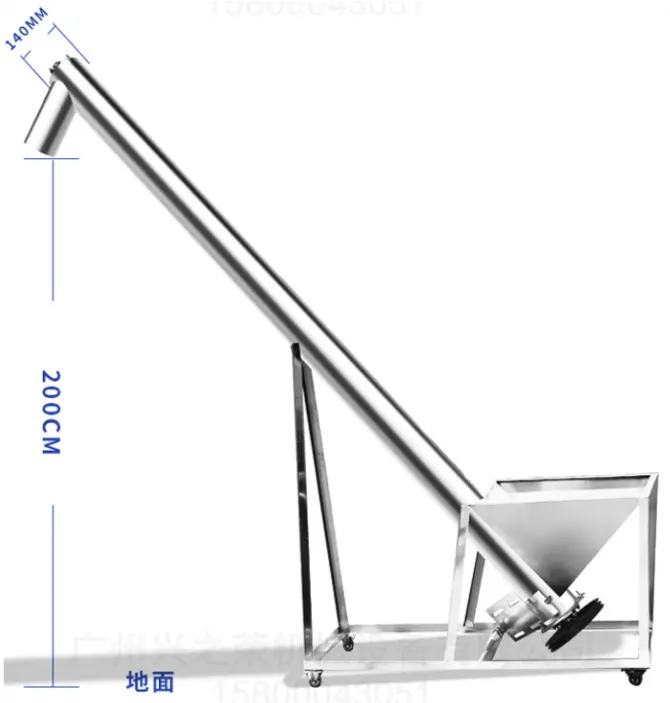

The packaging accuracy of a packing machine mainly depends on the measuring method. The most common feeding method for small powder packing machines is spiral feeding, which does not involve real-time weighing and belongs to the volumetric measuring method. The consistency of the capacity of each pitch of the screw is the basic condition that determines the measuring accuracy of the small powder packing machine. Of course, factors such as pitch, outer diameter, bottom diameter, and shape of the screw blades will also have an impact on the packaging accuracy and speed of the small powder packing machine. Let's explain them one by one:

◆ Factors Affecting powder packing machine machine packing accuracy

1. Screw pitch

For example, our spice powder packing machine uses a screw with an outer diameter of φ30mm to package 50g of cumin powder. We have chosen a pitch of 22mm, which has an accuracy ratio of over 80% for ±0.5g and over 98% for ±1g. However, we have seen that some customers previously used a curry powder packing machine with a screw of φ30mm outer diameter and a pitch of over 50mm, which resulted in a fast feeding speed but a measuring accuracy of around ±3g.

According to the industry standard “QB/T 2501-2000” (which is not a national standard), for a weighing instrument of Class X(1), when the packaging specification is ≤50g, a deviation of 6.3% is allowed. In other words, a deviation of ±3.15g is considered to be in compliance with this standard. However, for users, the packaging accuracy of the powder packing machine is directly related to product cost. When both machines meet the X(1) standard, the higher the packaging accuracy, the smaller the error, and the lower the cost. It is clear which one is better!

2. Outer diameter of the screw

The outer diameter of the screw is directly related to the packaging accuracy of the powder packing machine. As mentioned earlier, there is a direct relationship between the packaging accuracy of the powder packing machine and the screw pitch. However, before considering the relationship with the pitch, it is necessary to determine the size of the screw outer diameter for comparison.

Generally, when selecting the measuring screw for the powder packing machine, it is usually determined based on the size of the packaging specification, taking into account the material density to make appropriate adjustments. For example, when packaging 100g of pepper powder using our spice powder packing machine, a screw with a diameter of 38mm is usually selected. However, if packaging densely-packed glucose that weighs the same 100g, a screw with a diameter of 32mm should be used. In other words, the larger the packaging specification, the larger the selected screw outer diameter should be. This can ensure both the powder packing machine speed and the measuring accuracy.

◆ Factors that determine the efficiency of powder packing machine

Based on the previous analysis, we can see that the factor that determines the packaging efficiency of powder packing machine is actually the volume of the screw pitch. The screw will dispense materials corresponding to a certain volume when it rotates for a certain number of turns, which corresponds to the packaging specification. If the number of turns is too high, accuracy is improved but packaging speed is slower. On the other hand, if the number of turns is too low, the speed increases but accuracy naturally decreases. Our spiral design philosophy is to complete one measurement by rotating the screw 10-15 times. Of course, this is just providing customers with an ideal. Ultimately, it depends on whether users prioritize powder packing machine speed or packaging accuracy.

◆ Other factors affecting the efficiency of powder packing machine

Although the factor that determines powder packing machine speed is the volume of one screw pitch, other factors cannot be ignored either.

1. Shape of the screw blade

The cross-section of conventional screw blades is rectangular with a chamfered top, which is suitable for packaging most materials. However, for powdered drugs that use glucose or glucose as carriers, screw blades with a triangular cross-section should be used to prevent material from leakage the screw rotates abruptly to a stop.

2. Structure of the material cup outlet

This mainly refers to the anti-leakage ring, which should be set according to the material. If the material has good flowability and tends to drip when the measurement is completed, an anti-leakage ring should be added.

3. Auxiliary agitator in the material bin

The structure of the agitator in the material bin should ensure that the material can move sufficiently during stirring without exerting additional pressure on the material. The current configuration of agitators is to equip two, some of which are the same on both sides, while ours has two agitators with different structures: one is the main agitator for loose materials, and the other ensures that the material level is as horizontal as possible. Additionally, there are two working modes of the agitator: continuous and intermittent, which can be freely switched by the control panel of our powder packing machine.

◆ How to choose the right screw

Currently, the mainstream filler automatic powder packing machine on the market uses a screw to feed the material. In order to improve the powder packing machine speed and maintain packaging accuracy, it is crucial to choose a suitable screw. Only by selecting the appropriate screw can we maximize the powder packing machine speed, reduce feeding time, and not affect the measurement accuracy.

The size of the screw is divided by its visible diameter. Different material properties require different screw pitches. So, how to choose a suitable screw? This depends on the specifications of the product, which is the packaging dosage per bag. Choose the diameter of the screw according to the dosage size and determine the screw pitch based on the material properties. Only experienced powder packing machine manufacturers know how to operate this selection process.

You can tell us your specific packaging requirements, such as what materials to pack, the weight of each bag, output requirements, etc., and we will provide you with suitable types of pouch packing machine recommendations and packaging solutions.

+86 19112905173

+86 19112905173