Nuts Packing Machine

Nuts Packing Machine Price: USD 700 – 8000

◆ Automatic pouch packing machine description

This nuts automatic packing machine is a granule weighing & packing machine mainly used for packing non-sticky granular materials, such as nuts, peanuts, millet, melon seeds, raisins, whole grains, wheat, medicine granules, etc. It is a fully automatic pouch packing machine which is fully automatic operation, stepless speed regulation, high efficiency and stable quality. It is very helpful for your business.

◆ Pouch packing machine automatic characters

1. Fully automatic operation

Only need to input all the data in one time, this fully automatic pouch packing machine can realize automatic intelligent measurement, bag making, filling, packaging, sealing, cutting and other packaging processes. No need extra manual work.

2. High packing efficiency

One nuts automatic packing machine can packing 6 times of worker's job, greatly improves the packing efficiency and saves the labor cost for enterprise.

3. Stepless speed regulation

Instead of regulate feeding and packing speed by three gears of "fast, medium and slow", this nuts automatic packing machine takes a stepless speed regulation, with gentle and natural changes, less impact on pouch packing machine parts, make the machine has a longer service life.

◆ Packing machine parameters

| Product name | Nuts automatic packing machine |

|---|---|

| Model No. | YS-220L |

| Automation grade | Full automatic |

| Packing range | 1-100g (3-100ml) |

| Bag length | 30-170mm |

| Bag width | 30-100mm |

| Packing speed | 30-60 bags/min |

| Power supply | 220C/50HZ |

| Power | 1.4KW |

| Machine size | 900*1100*1590mm |

| Machine weight | 400kg |

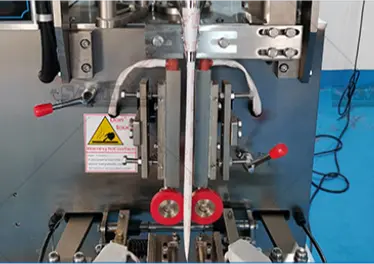

◆ Pouch packing machine structure

◆ Detailed pouch packing machine design

•Film feeding structure - film shaft

The linkage film shaft coordinates the whole film pulling process; has cursor offset correction function, suitable for various packing materials, the film pulling is smoother.

•Stocker - measuring cup weigher

Made of 304 stainless steel, high quality and hygienic; accurate in measurement, stable and durable; the packaging capacity can be adjusted at will.

•Control device-PLC control

Receive various instructions, can write different programs, and complete these instructions.;

•Sealing device - sealing roller

Accurate sealing, exquisite bag making; high temperature sealing, temperature can be adjusted freely; various bag types can be customized, such as back seal, three-side seal, four-side seal, etc.

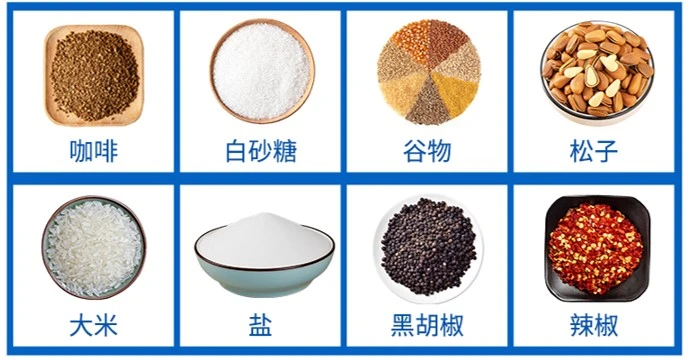

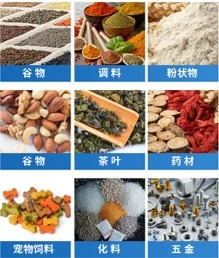

◆ Packing application

This nuts automatic packing machine has wide range of packing applications, it is mainly used for the packaging of non-sticky granular, strip, block and other materials, such as peanuts, millet, nuts, melon seeds, raisins, grains, wheat, seasoning, medicine, animal feeds etc.

Note: If your product is not listed here, please don't worry! We can customizepouch packing machine automatic for you according to your needs. Just tell us: weight or bag size requirements.

◆ Customizable bag type

Different pouch packing machine and packaging bag formers correspond to different packaging bag types, please contact us for more bag customization.

◆ More real pictures

◆ Nuts packing machine price

The nuts packing machine price is vary by different specification and packing use, the price difference is hard to see from machine appearance, it is more reflected in different functions and performance. Welcome to contact us for exactly details communication.

◆ Pouch packing machine manual

Automatic pouch packing machine instructions

This pouch packing machine automatic is widely used in quantitative packaging of non-sticky light solid, strips and block materials, such as cereals, hardware accessories, electronic accessories, tea, granule medicine, medicine powder, etc. It is composed of quantitative filling machine and pouch packing machine. Here are the instructions:

1. Before use, please remove the 4 screws on the bottom plate of the quantitative filling machine.

2. Plug in the power, turn on the switch on the side of the fully automatic pouch packing machine, the indicator light on the control panel will be on, the pouch packing machine will beep, then the machine will automatically reset and enter the standby state.

3. Pour the products that need to be packed into hopper of the fully automatic pouch packing machine, and press the "plus/minus" key on the control panel to set the packaging weight you need.

4. Set the speed by pressing "fast, medium, slow" on the control panel (depending on product size).

5. After the speed is selected, press the “start” button on the control panel, and the pouch packing machine enters into a fully automatic state, continuously quantitatively dispensing.

6. During the packaging process, if you need to pause or the packaging has been completed, you can press the “stop” button to make the machine stop and stand by.

7. The package quantity will be displayed in the "quantity column". If you need to clear the displayed value, please turn on and off the automatic pouch packing machine again or press the “reset” button.

8. To remove the products inside the machine, please press and hold the discharge button for 5 seconds, and the granule pouch packing machine will enter the discharge state.

9. After subpackaging, if you will not use this pouch packing machine in a short time, please turn off the power switch.

Maintenance of automatic granule packing machine

1. The auto granule packing machine should be used in a dry and clean place, not in the places where the air contains alkalis and other gas products that are corrosive to the human body;

2. If the granule pouch packing machine shakes during operation, please adjust the M10 screw on the front bearing to the appropriate position. If the shaft sleeve shakes, please calibrate the M10 screw at the back of the bearing frame to the appropriate position, adjust the gap so that the bearing does not make noise. Turn the belt pulley by hand, to see if the tightness is appropriate, too tight or too loose can make the automatic pouch packing machine a high probability of damage;

3. Regularly maintain the pouch packing machine and spare parts, once a month, check the worm gear, worm, anchor bolts on the lubricating block, see whether the bearings and other active parts are smooth rotation and wear, and if any faults are found, should repair in time;

4. After the pouch packing machine small stop work, the rotating drum should be removed for cleaning and clean the left products in the hopper, and then installed properly to prepare for the next pouch packing machine working.

5. If the pouch packing machine will not be used in short time, be sure to wipe and clean the whole machine body, coat the shiny surface of the pouch packing machine spare parts with rust inhibitor, and cover the complete fully automatic pouch packing machine with a cloth.

Cleaning and maintenance of fully automatic pouch packing machine

A. Fully automatic pouch packing machine cleaning:

•The metering parts should be cleaned in time after the pouch packing machine automatic(https://www.machines-packing.com/0-automatic-tea-pouch-packing-machine/) finish work. Especially for high-sugar materials, such as sugar, granules, etc., it is necessary to ensure that the turntable and the feeding port can be cleaned every shift.

•Clean the heat-seal body frequently to ensure that the seal lines of the finished packaging bags are clear.

•Scattered materials should be cleaned up in time to keep the pouch packing machine parts clean so as to prolong the service life.

•Clean the light-emitting head of the photoelectric switch (electric eye) frequently to ensure its working reliability.

•Frequently clean the dust in the electrical control box to prevent electrical faults such as short circuit or poor contact.

B. Lubrication of pouch packing machine automatic:

•Regularly lubricate the meshing parts of the gears, the bearings with seats and the oil injection holes of the moving parts with lubricating oil, once per shift.

•It is strictly forbidden to run the reducer without oil. After running for 300 hours at a time, clean the inside of the automatic stand up pouch packing machine and replace it with new oil, and change the oil every 2500 hours after that.

•When you want to refuel lot of oil, please don’t drop the oil on the transmission belt to avoid slipping or damage the transmission belt due to premature aging.

C. Automatic pouch packing machine maintenance:

•Frequently check the screws of each pouch packing machine parts to ensure that there is no looseness.

•Pay attention to waterproof, moisture-proof, anti-corrosion and rodent-proof for electrical components. Make sure the inside of the electrical control box and the wiring terminals are clean to avoid electrical failures.

•When the granule packaging machine stops running, the two heat-sealed bodies should be kept in an open state to avoid scalding the packaging materials.

+86 19112905173

+86 19112905173