Mechanical punch press machine

Punching Capacity: 100t

Mechanical punch press price: 9000 dollars

● Advantages of mechanical punch press

- the mechanical punch press machine offers 100 tons to do the punching work.

- Compared with traditional machining, the mechanical punch press for sale saves materials and energy and has high efficiency.

- the mechanical punch press can make products that cannot be produced by mechanical processing by using various dies and the cost is low.

● Specification Of Mechanical Punch Press

| Nominal Force(ton) | 100 |

| Nominal Stroke(mm) | 120 |

| SPM (times/min) | 45 |

| Die Height Adjustment(mm) | 50 |

| Between Slide Center and Frame(mm) | 320 |

| Bolster(mm) | 900*600mm |

| Blanking hole diameter(mm) | 290mm |

| Main Motor Power | 380v trifasico.7.5KW |

| Outline Dimension(mm) | 1400*1800*2650mm |

| Net Weight(kgs) | 5100kgs |

● SHIPPING

We have own professional agent, we can ship the machine in full container load and less than container load. Our good service and good price have satisfied many customers.

Our company has a professional mechanical punch press technical team, which can provide you with mechanical punch press and suitable solutions for your products, provide inspection and maintenance plans, and provide spare parts and accessories for the machine.

● Products of mechanical punch press

The mechanical punch press can be used in many industries: automobiles, cold cut metal saw parts, kitchenware, electrical appliances, motorcycles, tricycles, furniture, machinery and electronic components, etc.

● FREQENT ASKED QUESTIONS

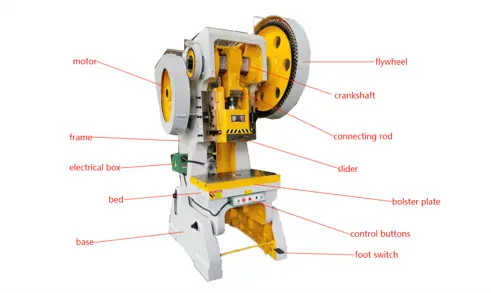

Main parts of mechanical punch press and its functions

The mechanical punch press can be used to produce many products and its structure is very simple, thus the mechanical punch press is a machine commonly used in production. The main parts of the mechanical punch press machine include:

1, Frame: The frame provides the structural support for the entire machine. It must be rigid and sturdy to withstand the forces generated during the punching process.

2, Bed: The bed is a flat surface where the workpiece is placed for punching. It is typically made of cast iron or steel and provides a stable base for the punching operation.

3, Ram: The ram, also known as the slide, is the moving part of the machine that delivers the punching force to the workpiece. It is guided by the frame and moves up and down.

4, Clutch and Brake: These components control the motion of the ram. The clutch engages and disengages the power transmission from the motor to the flywheel, while the brake stops the motion of the ram when needed.

5, Flywheel: The flywheel is a heavy rotating wheel connected to the main drive shaft. It stores and regulates energy to provide a smooth and consistent punching action. The rotational inertia of the flywheel helps maintain a constant speed during operation.

6, Motor of mechanical punch press. the motor converts electrical energy into circular motion of the flywheel. the flywheel of the mechanical punch press is driven by the motor in a circular motion and transmits the circular motion to the clutch and gears. And the punch press mechanical clutch transmits the circular motion to the crankshaft. One end of the connecting rod is connected to the crankshaft, and the other end is connected to the slider. the connecting rod moves with the crankshaft and this movement becomes the up and down movement of the slider.

7, Punch Holder: The punch holder securely holds the punch tooling, which includes the punch and die. It allows for easy replacement of tooling depending on the punching requirements.

8, Control System: This includes various controls and switches to operate and monitor the machine. It may include features such as an emergency stop button, control panel, and safety mechanisms.

9, Lubrication System: A punch press machine requires lubrication to reduce friction and prevent wear on moving parts. The lubrication system ensures smooth operation and extends the lifespan of the machine.

10, Safety Features: Punch press machines are equipped with safety mechanisms to protect operators from accidents. These can include safety guards, light curtains, and interlocks that prevent operation when safety conditions are not met.

11, Die punch press machine: Dies are very components of the mechanical punch press machine. to finish the punching work two dies are are required. the upper die is fixed on the slider with screws and moves up and down with the slider and the lower die is fastened on the bolster plate. The piece of metal is placed on the lower die and the upper die hits the metal and the lower die when the upper die comes down. the design and production of the upper and lower dies are determined according to the shape of the product to be produced.

+86 19112905173

+86 19112905173  877657530@qq.com

877657530@qq.com