700mm flow wrap machines

600mm mini flow wrap machine price: 8100 USD

Flow wrap machines are suitable for packaging various solid products, such as bread, biscuits, chocolates, candies, fruits, vegetables, meats, seafood, instant noodles, etc.

The horizontal flow wrap machine has fast packing speed, high efficiency, good packaging effect, and easy operation. It can be adjusted according to different products and packaging requirements, such as packaging speed, temperature, sealing time, cutting length, etc.

In addition, flow wrap machines can be equipped with various devices, such as inflating equipment, needle equipment, labeling device, exhaust device, etc., to meet different packaging needs.

◆ Horizontal flow wrap machine specification

| Flow wrap machine film width | Max 700mm |

| Bag width | 50-330mm |

| Product height | Max.110mm |

| Film roll diameter | Max 320mm |

| Packaging rate | 160bag/min |

| Packaging materials | BOPP、OPP、OPP-CPP、OPP-PE、ALU-FILM-PE |

| Machine weight) | 800kg |

| Power | 220V |

| Machine size | (L)4250mm × (W)940mm × (H)1650mm |

| Optional device | coding machine, Gas-filling device, Cake falling device, Sorting machine |

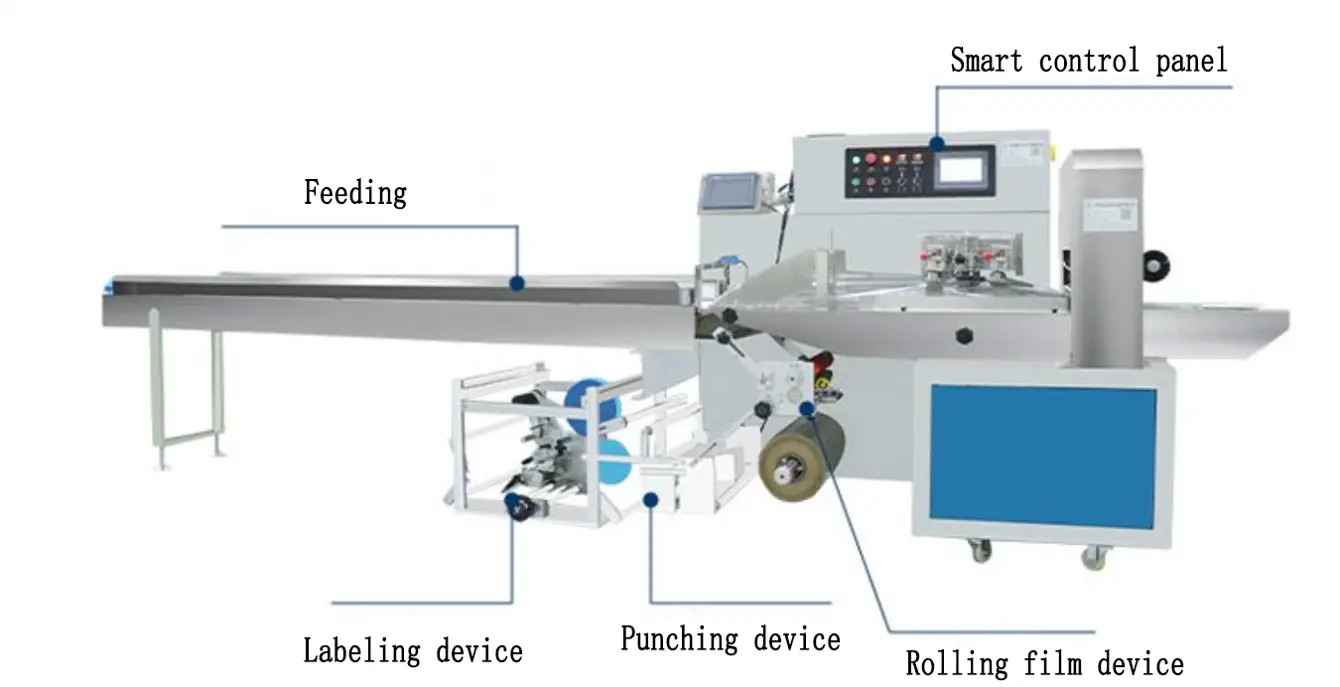

◆ Flow wrap machines structure

◆ Flow wrap machines application

Flow wrap machines for sale is an automated packing machine which is widely used and adaptable. It uses continuous plastic film to wrap vegetables, biscuits, instant noodles, chocolate, bread, and other foods, as well as medicine, daily necessities, and parts, forming a sealed package. The flow wrap machine for sale is a widely used mechanical equipment in the packaging industry. It can adjust the size and shape of the packaging according to the needs, to accommodate different types and sizes of products. Using the flow wrap machines to package products, can extend their shelf life, maintain their freshness and quality, and also improve packaging efficiency and the neatness of the product's appearance.

If you want packing small size products, please check our small flow wrap machine: 250mm mini flow wrap machine and 320mm small flow wrap machine.

◆ Optional device

Our Flow wrap machines can be equipped with additional devices to increase their functionality. Users can learn about the functions of different accessories in this article.

◆ How to choose small flow wrap machine ?

1. Product size and shape: Small flow wrap machine is suitable for long, thin or flat products such as biscuits, chocolate, and bread. Therefore, it is necessary to choose a flow wrap machine packing that is suitable for the size and shape of the product.

2. Packaging speed: Different flow wrap machine pouch have different packaging speeds, so it is necessary to choose an appropriate flow wrap machine for sale based on your production scale requirement.

3. Packaging material: Small flow wrap machines are suitable for flexible packaging materials such as BOPP and CPP. So you need to choose suitable packaging materials based on the characteristics of the product.

flow wrap machine south Africa

4. Packaging effect: The packaging effect can be adjusted according to your needs, such as packaging tightness and appearance. You can choose an appropriate packaging effect based on the characteristics of the product and market demands.

5. Machine stability and reliability: Choosing a flow wrap machine China with stability and reliability can reduce equipment failures and downtime, and improve production efficiency.

In summary, choosing a suitable small flow wrap machine requires comprehensive consideration of the above factors, and making a decision based on production needs.

◆What is the difference between vertical packing machine and flow wrap machine?

Vertical packing machine and horizontal flow wrap machine are two different types of packing machine, do you know what are the differences between them?

(1) The structure is different

Vertical packing machine refers to a standing machine, which completes the packaging process from top to bottom, so its height is relatively high, but it occupies less area.

Horizontal flow wrap machine is a horizontal machine, and the material conveying process is horizontal, so the height is low, but it occupies a larger area.

2. Works differently

Vertical packing machine: The items to be packaged are vertically filling. The packaging material roll is usually at the upper end of the pouch packing machine. The material roll is made into a formed bag by a vertical bag former, and sealed by the heat longitudinal sealing device. Then the products fill into the bag, and complete the sealing, bag cutting and other processes.

Horizontal flow wrap machine: The packaged items are horizontally conveyed to the flow wrap machine film inlet by the conveying mechanism (at this time, the flow wrap machine film has been in a cylindrical shape through the bag former, and the packaged items will enter the packaging material), and then go through the processes of heat sealing, pumping (vacuum packaging) or air supply (inflatable packaging), cutting and so on.

3. Applicable packaging objects are different

Vertical packing machine is more suitable for the packaging of small or irregularly shaped materials such as granules, powders, and liquids because of its vertical feeding method.

flow wrap machines] are more suitable for packaging block, strip, spherical and other larger items with relatively fixed shape or for the situation where multiple items are packaged at the same time. It is widely used in food, stationery, hardware, cosmetics and other industries, such as: vegetables, noodles, bread, cakes, chocolates, biscuits, paper towels and other foods packing.

4. Packaging style is different

Vertical packing machine can produce various bag styles, such as pillow bags, gusset bags, and stand-up pouches. Flow wrap machines produce a sealed, pillow-style package.

5. Packing speed is different

Vertical packing machine can operate at high speeds, some models even can produce up to 200 bags per minute. Flow wrap machines are also high-speed machines, but typically operate at slightly slower speeds.

6 Packaging costs :

Vertical packing machine price is relatively low, while the flow wrap machine price is relatively higher. Under the same configurations, the flow wrap machine price is around 30% higher than the vertical packing machine.

Customers can first select the appropriate type of packaging equipment according to the products form and characteristics, and then comprehensively consider factors such as packaging size, packaging weight, and packaging speed etc.

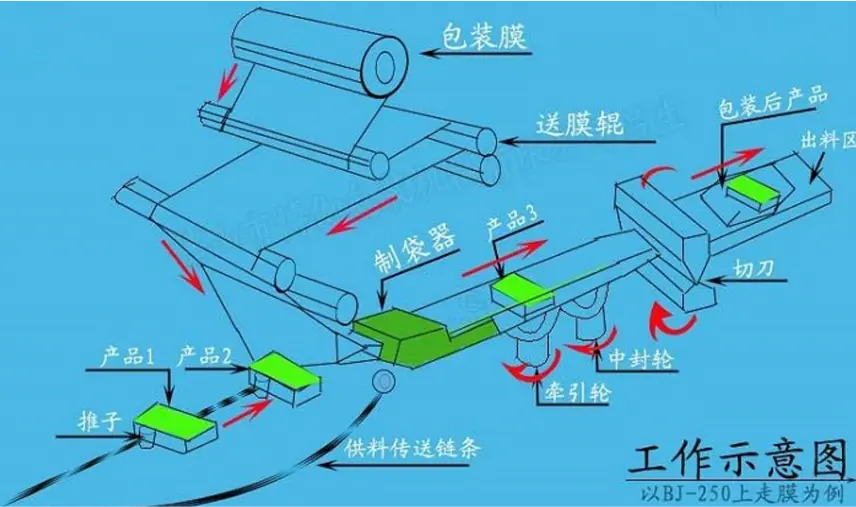

◆ Flow wrap machine working principle

Flow wrap machine for sale is a fully automatic packaging machine with strong packaging ability and suitable for food and non-food packaging of various specifications. It can not only be used for the packaging of non-logo packaged products, but also can be used for high-speed packaging with pre-printed logo roll materials.

The flow wrap machine film is installed on the shaft roller, and the packaged product is placed in the feeder (if it is an irregular product, it must be fed manually), and will be transfer to the packaging position by the conveyor belt automatically. Then the products will be packed in the flow wrap machine film and then heated and pressed into shape. After that, it is sent to the horizontal sealing cutter for heat-melting, sealing and bag cutting, finally the finished product is output by the conveyor belt.

◆ Flow wrap machine troubleshooting

There will always be common failures in the long-term application of mechanical equipment(such as the flow wrap machines, so everyone must prepare in advance to master some flow wrap machine troubleshooting, which will help us to be able to immediately fix them in case of small flow wrap machine problems occurs.

1) The small flow wrap machine seal will have burnt and wrinkled marks when the temperature is too high or the speed is very slow, and or the temperature resistance of the outer membrane surface is poor.

Flow wrap machine troubleshooting method: adjust the small flow wrap machine speed, lower the temperature, and replace the plastic film material.

2) The cutting knife will cut on the product when the small flow wrap machine knife seat is too high or too low, or the packaging speed is too fast, and when the swing bar and the cutting knife are not synchronized.

Flow wrap machine troubleshooting method: reduce the packaging speed and adjust the height of the end sealing member so that the center of the sealing knife is in the middle of the product height.

3) The cutting position will deviate from the color mark when the color of the flow wrap machine film color mark is too light, the film drive slips, and the color mark tracking is not turned on.

Troubleshooting method: refer to the packaging machine manual to adjust the sensitivity of color mark tracking; in the man-machine dialogue interface, switch the tracking mode to "tracking cut".

4) The thermometer cannot control the temperature when the solid breaker is burned out or the temperature control meter is damaged and or the thermal resistance is damaged.

Troubleshooting method: replace the flow wrap machine packing thermocouple, replace the temperature control meter (see Figure 1), and replace the heating element.

5) If the sealed air flow wrap machine speed is too fast, the heat seal ability of the inner layer of the outer film will be poor, and when the temperature is too low, the seal will leak or become weak.

Troubleshooting method: slow down the speed, increase the temperature, and replace the material of the flow wrap machine film.

6) When the standard air pressure is wrong, the swing rod of the cylinder is loose, the heating temperature is low, and the pressing roller and the driving roller are not parallel, poor heat sealing will occur.

The way is to adjust the parallelism, adjust the temperature and standard air pressure to tighten it.

If you want more knowledge about flow wrap machine, such as flow wrap machine troubleshooting of sealing folds(wrinkles), you can cleck our blog for more information.

+86 19112905173

+86 19112905173