450mm flow wrap machine for sale

450mm horizontal flow wrap machine price:6400 USD

Flow wrap machine is a continuous packaging machine with very strong packaging capacity and suitable for various specifications for food and non-food packaging. It has a wide range of uses and can be used in hardware, medical supplies, food, daily necessities and other industries. The packaging is tight and air-tight, which can isolate air, keep fresh, and prevent scratches.

The flow wrap machine for sale is equipped with advanced programmable logic controller (PLC) and servo motor technology, it can realize fully automatic packaging operation, including feeding, filling, bag making and sealing. This mini flow wrap machine can realize high-speed packaging rate, and the packaging speed can be adjusted according to the specific requirements of different products, greatly improve packaging efficiency and reduce costs.

◆ Horizontal flow wrap machine specification

| Film width | Max 450mm |

| Bag width | 50-210mm |

| Product height | Max.75mm |

| Film roll diameter | Max 320mm |

| Packaging rate | 160bag/min |

| Packaging materials | BOPP、OPP、OPP-CPP、OPP-PE、ALU-FILM-PE |

| Machine weight) | 650kg |

| Power | 220V/3.2kw |

| Machine size | (L)4020×(W)800×(H)1450 |

| Optional device | coding machine, Gas-filling device, Cake falling device, Sorting machine |

| The above parameters are for reference only, and can be customized according to customer needs, subject to the actual product. | |

◆ Flow wrap machine for sale application

Horizontal flow wrap machine has a wide range of applications. It is suitable for the packaging of food industry, pharmaceutical industry, daily necessities, disposable products, hardware products, plastic products, toy stationery, industrial supplies, industrial parts, auto parts and other products. The most on the market is used as flow wrap food packaging machines such noodle flow wrap machine, chocolate flow wrap machine, flow wrap machine for biscuits, vegetables etc. and also for industry use like flow wrap machine for paper and so on.

According to different packaged products, the compact flow wrap machine model will be different, please contact us for more communication, as a professional flow wrap machine manufacturer, we will give your correct suggestion to meet your actually requirements.

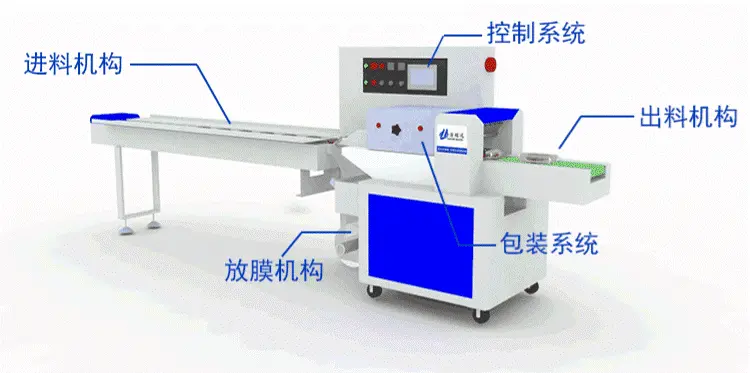

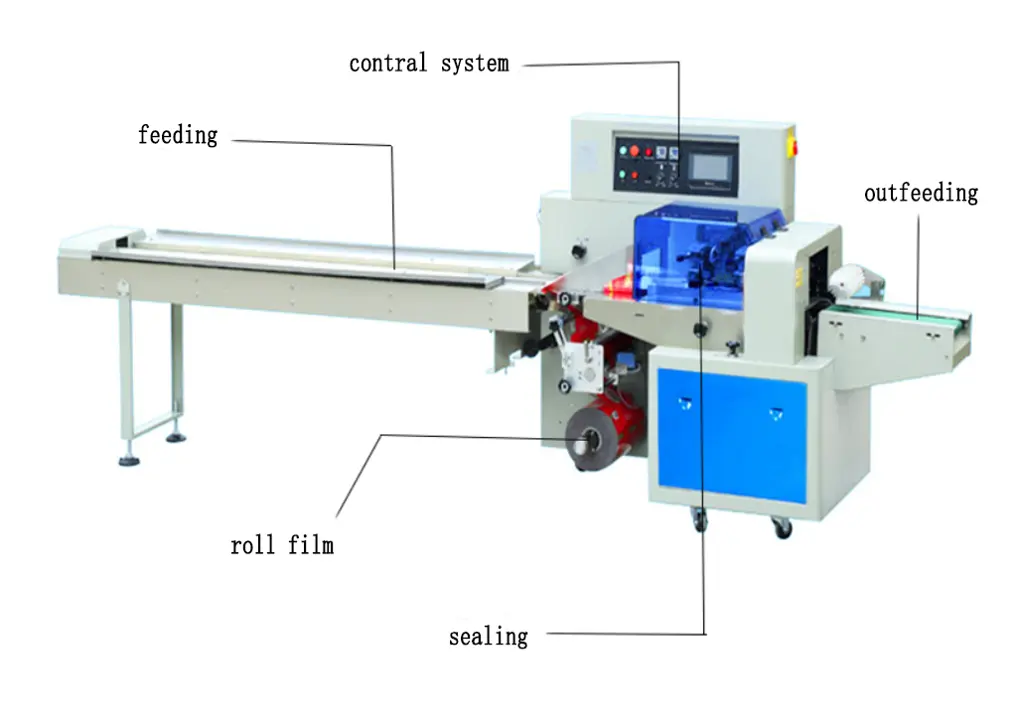

◆ flow wrap machines structure

◆ details

-

•Smart Computer

The computer can store 40 groups of packing parameters, it is fast to change products. -

•Photoelectric

Photoelectric can detect the position of the product when packing. There is no requirement for the location of the product, so feeding spend is fast. -

•Bag Making

The sizes of bag making can be adjusted according to different products. The max Bag width is 210mm. -

•Severo Motor

The severo motor runs fast and stable. we can adjust severo motor speeds according to different products.

◆ Transport packaging for flow wrap machine

Based on rich oversea sales experience, we know how to protect our high speed flow wrap machine from damaged. Our flow wrap machines are packed in wooden cases, we use carton and wooden packaging double protection measurement to ensure the machine will not be damaged during transportation.

◆ About us

We treat each of our customers seriously, choosing us can really give you an efficient and worry-free shopping experience.

We have good loading and custom declaration capacity;

We are professional flow wrap packaging machine manufacturer with rich exportation experience.

We have a professional transportation team to deliver the pillow packaging machine you purchased to your location safely and quickly;

for many years we sell our machines to different countries, you can see our flow wrap machine South Africa, flow wrap machine Europe, flow wrap machine UK, flow wrap machine Australia. We also sell to flow wrap machine manufacturer in India such as flow wrap machine manufacturer in Mumbai, Faridabad, Ahmedabad etc.

We have a professional technical team, our flow wrap machine engineer can provide you offline technical support especially when flow wrap machine repair, and also can help teach your flow wrap machine operator.

We also provide flow wrap machine spare parts to ensure you have enough flow wrap machine parts to replace when some parts wear out.

◆ Flow wrap food packaging machines advantages

Our flow wrap food packaging machines can automatic feeding and packing. One machine can pack more than 10 different specifications. It has advanced design, stable and reliable performance and below advantages:

1. High intelligence. Flow wrap food packaging machines are highly intelligent and can be programmed to automate the entire packaging process, including weighing, bag making, filling, sealing, coding, and bag cutting. This reduces the need for manual labor and improves efficiency.

2. Fast packing speed. High speed flow wrap machine has capacity to pack more than 140 bags per minute, making them ideal for high-volume production environments.

3. Simple operation. All parameters of the flow wrap machine for sale are controlled by PLC and set via a computer. This makes the flow wrap machine operator easy to operate after be simple training.

4. Good packing effects. The sealed air flow wrap machine can be used for high-speed packaging of non-branded packaging materials and pre-printed logo patterns designs roll materials. The packaging is tight and beautiful, and is deeply loved by users.

5. Personalized customization. Flow wrap machines can be customized according to specific requirements, the size of the packaging bag and the width of the flow wrap machine film can be adjusted. They can also be combined with other equipment such as coding machines, gas-filling devices, cake falling devices, and sorting machines to increase functionality.

6. Wide range of use. Flow wrap food packaging machines have a wide range of applications and can be used in various industries such as medicine, food, and hardware, with the packing size being adjustable to suit different products.

◆ How to calculate the flow wrap machine film size

In order to make our products can be packaged beautifully and tightly, we need to fix the appropriate flow wrap machine film size. so how to calculate the roll film size?

Kindly note, the width of the flow wrap machine film is determined by the size of the product being packaged, while the length is determined by the flow wrap machines model. Let’s illustrate better with an example.

First, let’s assume the product length 65mm x width 50mm x thickness 5mm, and the sealing length is 30mm.

So, we will see:

Flow wrap machine film width = (product width + product thickness) × 2 + sealing length (30mm) = (50+5)x2+30=140mm;

Flow wrap machine film length: Each flow wrap machines for sale has requirements for the inner diameter and outer diameter of the packaging film, the film length should within the outer diameter.

For example, the 450mm flow wrap machines for sale introduced in this article, its inner diameter is 75mm and the max. outer diameter is 320mm. This means, your film length can’t make the roll outer diameter more than 320mm.

So we know that we need the packaging film with 140mm width and the roll outer diameter less than 320mm.

Expand: Each package length = product length + product thickness + sealing length = 65+5+30=100mm.

If your film outer diameter is more than 320mm, you can choose our other horizontal flow wrap machine model, such as 600mm Flow Wrap Machines, 700mm Flow Wrap Machine. Welcome to contact us for flow wrap machine photos, flow wrap machine video, flow wrap machine spare parts, flow wrap machine manual, flow wrap machine cost and other more details.

+86 19112905173

+86 19112905173