350 horizontal flow wrap machine

350horizontal flow wrap machine price:5500usd

horizontal flow wrap machine adopts a double frequency conversion controller, during the packing, the width of the bag can be changed according to different products. We can input the cutting sealing position through the touch screen because of the High sensitivity photoelectric eye color tracing function. The cutting sealing position is accurate and the operation is easy.

The other packing parameter(packing speed, bag width, sealing temperature, etc.) can be adjusted through the touch screen. horizontal flow wrap machine has advantages with high precision packaging, good packing effect, and high packing efficiency.

◆ horizontal flow wrap machine specification

| Film width | Max 350mm |

| Bag width | 50-160mm |

| Product height | Max.40-60mm |

| Film roll diameter | Max 320mm |

| Packaging rate | 40-230bag/min |

| Packaging materials | BOPP、OPP、OPP-CPP、OPP-PE、ALU-FILM-PE |

| Machine weight) | 580kg |

| Power | 220V/2.6kw |

| Machine size | L)4020×(W)770×(H)1450 |

| Remarks | Optional air filling device |

This horizontal wrapping machine can come into the production line.

◆ horizontal flow wrap machine advantages

1. servo system has high automation and Stable operation.

2. color touch screens can monitor the machine’s operation and set parameters easily.

3. fault self-diagnosis function can detect faults and show them on the touch screen.

4. High-sensitivity photoelectric eye color tracing makes the cutting and selling position more correct.

5. Temperature-independent PID control system suits different film materials.

6. CNC system can easy to adjust functions.

◆ application

Most products need to be packed for easy transport or long time storage. Good packing can improve the product appearance and extend the shelf life of products, so the horizontal wrapping machine has been widely used in Industry, the food industry, the daily necessities industry, etc. It is suited for packing solid products, such as Vegetables, fruits, hardware, bread, books, masks, toys, etc.

◆ horizontal flow wrap machine price

Due to the improvement in labor costs, factories are investing more time and energy into automation equipment to replace manual labor and reduce product costs. Our automated horizontal flow wrap machine has a high degree of automation and can replace up to 5 workers, improving packing efficiency and reducing costs. Our horizontal wrapping machine get more and more popular, so what is the horizontal flow wrap machine price?

4000usd-13000usd

Most factories prioritize the price, performance, and service life of the horizontal flow wrap machine. The cost of a horizontal flow wrap machine varies depending on the manufacturer, quality, and functions, ranging from 6000usd to 30000usd. Therefore, it is necessary to select a suitable horizontal flow wrap machine based on the packing requirements, such as product size and production scale. Our factory offers 250 mini flow wrap machine at 4600usd, 600mm flow wrap machine at a reasonable price of 8500usd, which is fully functional and can meet the needs of most scenarios. It significantly improves packing efficiency and quality.

◆ horizontal flow wrap machine working principle

horizontal flow wrap machine has a strong ability for packing solid products, and it is widely used in factories. How does the working horizontal flow wrap machine?

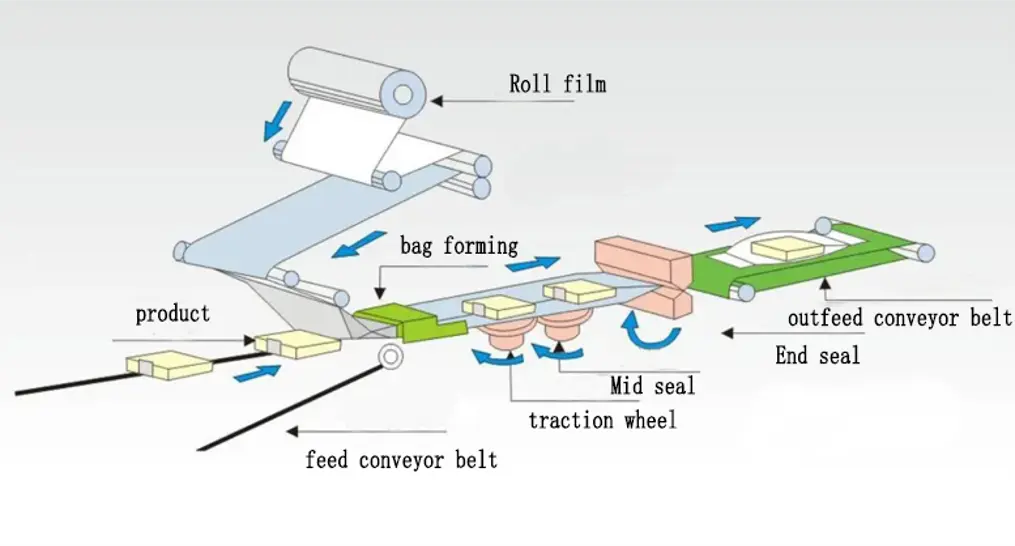

1. the products are placed on the feed conveyor belt, which sends them to the bag forming equipment

2. the bag forming equipment transforms the roll film into a cylindrical bag and packs the product into it.

3. the products pass through the mid seal and end seal through the traction wheel. The mid seals seal the back of the bag, while the end seals seal the two ends of the bag.

4. the products pass through the outfeed conveyor belt and are finished packing.

This image helps users understand the entire process of how the horizontal flow wrap machine works.

One of the advantages of the horizontal flow wrap machine is its ability to use packaging materials with or without marks and logo patterns. Unlike other packaging machines, this feature allows for more customization and branding opportunities. However, during the packing process, there may be positioning errors due to factors such as non-standard positioning points or stretching of packaging materials. To address this issue, the horizontal flow wrap machine uses a successive photoelectric positioning system that continuously compensates for errors and keeps positioning errors within a small range. This system ensures accurate positioning and improves the overall packing effect.

The horizontal flow wrap machine control system adopts high-quality CNC system, and it is easy to adjust functions and technology upgrades to improve corporate competitiveness

+86 19112905173

+86 19112905173