250 mini flow wrap machine

mini flow wrap machine price: 4600 usd

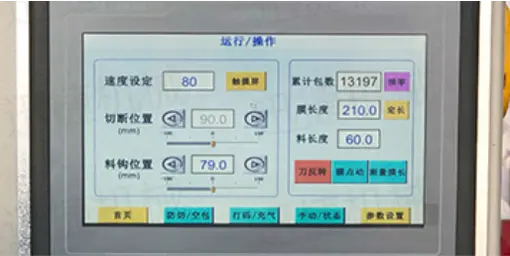

Mini flow wrap machine adopts a PLC control system and an intelligent touch screen. All electrical faults will be displayed on the touch screen, making it easy to operate after simple training and reducing the requirements of operators. We can set parameters such as bag length, sealing temperature, and packaging speed through the intelligent touch screen. Mini flow wrap machine can automatically complete the packing process, including feeding, bag making, date printing, inflation, exhaust, and automatic counting. This improves the packing efficiency and effect.

◆ parameters

| Film width | Max 250mm |

| Bag width | 30-110mm |

| Product height | Max.40-55mm |

| Film roll diameter | Max 320mm |

| Packaging rate | 40-230bag/min |

| Packaging materials | BOPP、OPP、OPP-CPP、OPP-PE、ALU-FILM-PE |

| Machine weight) | 450kg |

| Power | 220V/2.4kw |

| Machine size | (L)3770×(W)670×(H)1450 |

| Remarks | Optional air filling device |

The 250 compact flow wrap machine is a standard model. If the products you want to pack exceed the parameters of this machine, you can choose another larger model, such as the 350 flow wrap machine or 600 flow wrap machine. Alternatively, you can contact us for personalized customization.

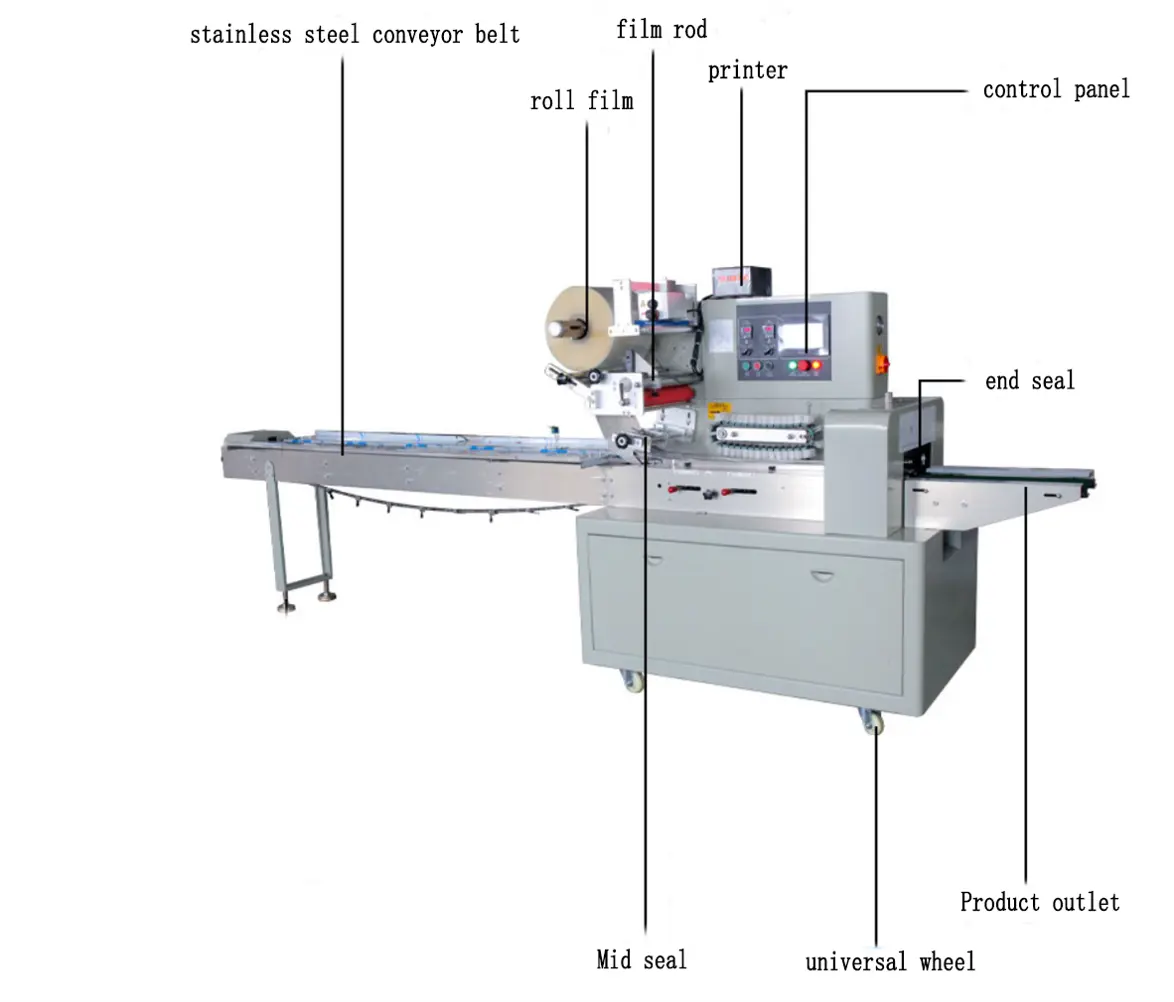

◆ structure

◆ application

Mini flow wrap machine revolutionizes traditional manual packing models by packing 80-120 products per minute, ensuring fast packing speed and clean products. It is suitable for packing various solid products.

·Food: egg yolks, fruits, biscuits, bread, cakes. Pastries, chocolate, instant noodles, and bread. cake, flowers vegetables, navel oranges, etc.

·Hardware accessories: medical masks, cotton swabs, gauze, disposable syringes. Eye drops, capsules, disposable medical gloves, and antipyretic plaster.

·Daily necessities: cleaning products, kitchen appliances, towels, soap, rubber gloves, cotton gloves, wire balls, cleaning cloth, daily gadgets, etc.

·Stationery and tools: cards. Erasers, erasers, big head pens, labels, pens, pencils, toys, stationery, etc.

·Disposable supplies: disposable hotel supplies, disposable tableware, disposable medical supplies, etc.

·Electronic products: batteries. Electrical appliances, appliances, manuals, remote control, data lines, wires. U disk, mobile phone shell, etc.

◆ details

-

•human-machine interface

Mini flow wrap machine has a user-friendly human-machine interface that allows users to set parameters easily. -

•Constant temperature end seal

The constant temperature end seal maintains a stable temperature, preventing curling and loopholes in bags, thus improving the overall packing effects. -

•stainless steel conveyor belt

The stainless steel conveyor belt makes products clean, and the operation is easy. -

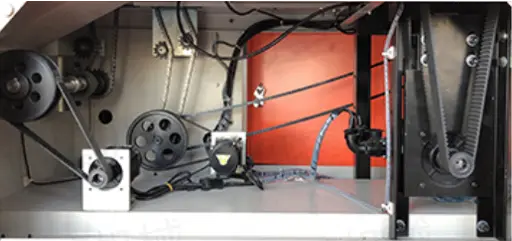

•Three servo control

This machine comes equipped with a touch screen that allows for the adjustment of feeding and cutting times. Additionally, the machine has a memory function that can store up to 40 parameters on the computer.

◆ flow wrap machine parts of free

| 1 | name | num |

| 2 | flow wrap machine manual | 1 |

| 3 | instruction manual | 1 |

| 4 | product certificate | 1 |

| 5 | servo motor manual | 1 |

| 6 | Photoelectric manual | 1 |

| 7 | Feeding module | 2 |

| 8 | mid seals electric heat pipe | 2 |

| 9 | end seals electric heat pipe | 2 |

| 10 | power cord | 1 |

| 11 | spanner wrench | 1 |

| 12 | Allen key | 1 |

| 13 | Phillips screwdriver | 2 |

| 14 | brass wire brush | 1 |

| 15 | needle-nose pliers | 1 |

◆ flow wrap machine considerations

1. Ensure there is no foreign matter on the machine table.

2. Install the packaging roll film, the direction of the packaging roll film is consistent with the feeding direction.

3.Turn on the power, after 3 seconds, the touch screen will run.

4.Measure the bag length (The distance between adjacent color marks, the unit is mm)

5.Press the start button and rotate the bag length adjustment handle (the bag length decreases clockwise, and the bag length increases counterclockwise). The bag length on the touch screen is consistent with the measured bag length value(Note: only the machine is running, users can adjust the bag length adjustment handle ).

6.Adjust the sealing cutter and the sealing cutter is on the color marks.

7.Adjust the cursor and the cursor is on the color marks.

8.Run the machine and check the sealing effect.

The flow wrap machine is controlled by a PLC, and parameters can be easily set through a touch screen. After simple training, the machine is easy to operate.So how to use flow wrap machine.

◆ Maintenance is very important, correct maintenance can improve the life of machines and stability.S o how to maintain the flow wrap machine?

1.Before cleaning the flow wrap machine, ensure that the power is turned off to ensure the safety of the operator.

2. Use a clean rag to wipe the working table and surface of the machine. For stubborn dirt, use a mild detergent solution and a soft brush to scrub the surface.

3. Clean any product debris on the feed mechanism, mid seals, and end seals. Use a soft brush or a vacuum cleaner to remove any debris that may have accumulated in these areas.

4. Use a greased wire brush to clean any film debris on the end seal knife. This will help to prevent the film from sticking to the knife and affecting the sealing quality.

5. Check the drive belt and conveying flat belt for any signs of wear or damage. If necessary, replace them with new ones to ensure smooth operation of the machine.

6. Check all kinds of wearing parts, such as the sealing cutter, cursor, and feeding belt. If any of these parts are worn or damaged, replace them in a timely manner to prevent any production issues.

7. Check the wear of the transmission part, such as the motor and gearbox. If the wear is serious, replace them in a timely manner to prevent any breakdowns or malfunctions.

8. Check and fasten the electrical wiring, and clean any dust or debris that may have accumulated on the electrical components. This will help to ensure that the machine operates safely and reliably.

If you need more details, you can click our flow wrap machine manual.

+86 19112905173

+86 19112905173