flow wrap machine manual Overview

◆ Introduction of flow wrap machine for sale

Flow wrap machine for sale is a type of continuous packaging machine with strong packaging capabilities that can accommodate a variety of food and non-food packaging specifications. The items to be packaged are horizontally fed to the packaging position via a conveyor belt, and the small flow wrap machine will automatically perform the packaging, sealing, and cutting processes.

1.Adopting the "cut and go" method, with high-sensitivity photoelectric eye color mark tracking, it will not seal empty bags or cut at an angle.

2.The horizontal flow wrap machine utilizes dual frequency converters to achieve one-step operation, saving time and packaging film.

3.The operation adopts a human-machine control interface, as well as automatic diagnosis function, making equipment faults clearly.

The control system of the horizontal flow wrap machine is achieved by advanced digital controllable software. This technology is convenient for technicians to adjust the functions of the horizontal flow wrap machine in the future, and enables timely improvement of packaging technology, making the small flow wrap machine more advanced and unique, rapidly enhancing its practicality and functionality.

The model of a flow wrap machine China generally indicates the maximum width of the flow wrap machine film that can be used with this flow wrap machine. For example, the 250mm Mini Flow Wrap Machine indicates that this mini flow wrap machine can use packaging films with a maximum width of 250mm. Similarly, 700mm Flow Wrap Machines indicate that the flow wrap machine for sale can use packaging films with a maximum width of 700mm.

As for choosing the appropriate width of the flow wrap machine film, it depends on the specific details of the products that you want to package. We have introduction on this topic in the "How to calculate the flow wrap machine film size" section at the end of the article 450mm Flow Wrap Machine For Sale. You can check for more details.

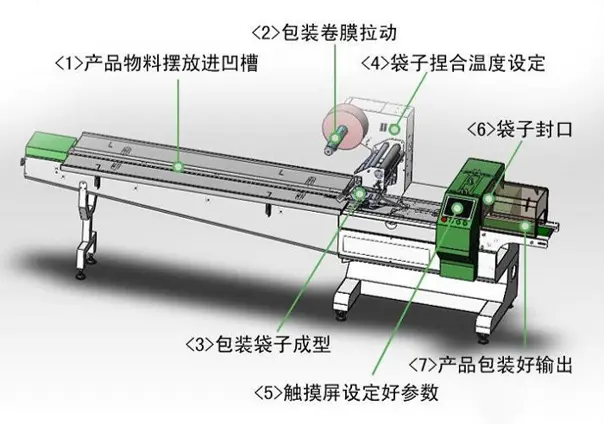

◆ flow wrap machines structure diagram

包装膜穿膜轴 Film perforation shaft

全不锈钢进料面板 All stainless steel feeding pane

l

不锈钢链条 Stainless steel chain

制袋器 Bag maker

启动按钮 Start button

控制界面 Control interfac

e

一体电箱 Integrated electrical box

电源开关 Power switch

端封刀座 End sealing knife holder

成品输送皮带 Finished product conveyor bel

t

机座 Machine base

可活动的固定脚轮 Movable fixed wheel

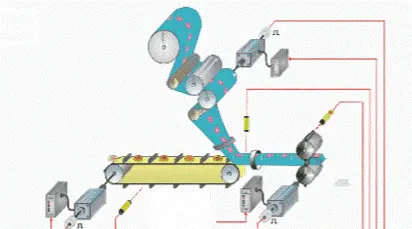

◆ flow wrap machine working principle

The compact flow wrap machine is driven by a stepless variable frequency motor, which rotates the chain gearboxes with triangular belts. The gearbox adjusts the speed through the variable speed chain, which enables different operating speeds and can adjust the conveyor length of flow wrap machine film. The output shaft of the gearbox drives the pressure roller of the flow wrap machine film through chain transmission, and the setting of the length of the output film can be manually operated on the chain speed controller.

In the packaging process, the color mark is monitored by photoelectric tracking. Meanwhile, the gearbox achieves the movement of the packaging object, conveyor belt, and paper pulling wheel, pressure roller, transverse seal, and finished product conveyor belt through multiple sets of chain transmission, completing the packaging of the item.

The conveyor belt automatically transports the packed items to the packaging position, wraps them in the flow wrap machine film, and then after heating and pressing, sends them to the transverse seal for heat sealing and cutting. The finished product is then outputted by the conveyor belt.

把产品摆放进凹槽 Place the product into the groo

ve

包装卷膜拉动 Pull the packaging film

包装袋成型 Form the packaging bag

包装袋封合温度设定 Set the bag middle sealing temperature

触摸屏上设定好参数 Set the parameters on the touch screen

包装袋封口和切断 Bag sealing and cutting

产品包装好后由输送皮带送走 The packaged products are sent away by the conveyor belt

◆ Application of compact flow wrap machine

The compact flow wrap machine is an automatic continuous shrink packaging equipment that uses quartz far-infrared tube heating, which is energy-saving and efficient (saving more than 15% on electricity). The shrinkage temperature and motor drive speed are stable and adjustable, with a wide adjustment range. And the machine has a unique drum self-rotation device that can work continuously.

The compact flow wrap machine is designed for the packaging of solid objects, mainly used for packaging various regular-shaped solid objects, such as food items like cookies, bread, mooncakes, candy, etc., as well as daily necessities, industrial parts, etc. They can all be packaged using flow wrap machines. It is widely used in the food industry, pharmaceutical industry, daily necessities, disposable items, hardware products, plastic products, toys and stationery, industrial products, industrial parts, automotive accessories.

It should be noted that for loose or individually separated objects, the packaged items must first be placed in a box or bundled together to form a whole before packaging on the flow wrap machines. As for other non-solid packaged items, it is also necessary to follow this operating procedure.

◆ Usage steps of flow wrap machines

1. Starting up

(1) Before starting the machine, remove the obstacles and people around the flow wrap machine for sale that affect the safe operation, and check whether the speed control knob is at the "zero" position.

(2) The startup sequence of thecompact flow wrap machine is as follows: vibrating screen --- feeding system --- conveyor belt --- bag cleaning machine --- bag arranging machine --- bag unloading machine --- packaging machine --- feeding machine.

(3) Rotate the speed control knob clockwise, gradually increasing to the operating speed, typically 3-5r/min. If there are no abnormalities, the operation can be performed.

2. Stopping machine

Firstly stop feeding, and then stop the machine in the following order: feeding machine --- empty the materials in the rotating cylinder --- packaging machine --- bag unloading machine --- bag arranging machine --- bag cleaning machine --- vibrating screen. Finally, clean and maintain the equipment.

3. Temporary stop and emergency stop:

(1) Temporary stop: If a temporary stop is required, the speed control knob should be rotated back to the "zero" position to stop the flow wrap machine, while simultaneously pressing the rotation stop button.

(2) Emergency stop: In the event of an unexpected accident, emergency stop measures should be taken by pressing the emergency stop button. At this time, all equipment except for the vibrating screen will stop working. After stop, the speed control knob should be rotated back to the "zero" position.

◆ Precautions

1. Before working, check the condition of compact flow wrap machine first, check and remove obstacles and other personnel within the safe operation range of the equipment. The low wrap machine operator must have safety awareness and be trained before starting work.

2. When working, the flow wrap machine operator should keep their body as far away from the equipment as possible and tie up their sleeves and clothes to prevent scraping or bumping.

3. When temporary shutdown is required, personnel are not allowed to approach compact flow wrap machine. If approaching is really necessary, the power supply of the rotating motor shall be cut off first.

4. The power supply should be cut off during maintenance. If a live inspection is required, a warning sign should be hung or someone specially assigned to monitor it.

5. During the working process of the flow wrap machine for sale, it is not allowed to touch the packaging bag to avoid affecting the measurement accuracy.

6. When flow wrap machine repair, it should be operated by a professional flow wrap machine engineer, and the equipment should be restored according to the technical requirements. After the equipment is used, it should be cleaned and inspected, pay attention to the sealing of the distribution box, flow wrap machine parts completeness and whether the screws of each section are loose, and there are any changes in required gaps.

Additionally, it should be noted that:

1. Before turning on the power, you must insert the induction aviation plug and lock the screw;

2. You should not use metal containers or lids and should avoid placing containers on a metal countertop when pressing the start button as it may damage the small flow wrap machine.

3. During operation, the flow wrap machine operator should frequently touch the surface of the sensor head and check if it is overheating. If it feels too hot, heating should be stopped and resumed after cooling down.

4. There may be high voltage in the body of flow wrap machines and the bottom plate may be electrified, so special attention should be paid during maintenance to avoid danger.

◆ flow wrap machine repair and maintenance

● Before cleaning and washing the used flow wrap machine, it is necessary to turn off the power to ensure human-machine safety.

● Use a clean and wet towel to clean the work surface and outer layer of the used flow wrap machine to ensure that it is not scratched. This type of cleaning,flow wrap machine repair and maintenance work should be conducted regularly.

● Use compressed air to clean the product debris in the feeding organization, middle sealing and end sealing of flow wrap machines for sale.

● Use a brush with the machine oil to remove the flow wrap machine film debris adhered to the end sealing, in order to avoid packaging materials remaining on the sealing, affecting the packaging of the next round of products and causing poor packaging results.

● When a solid state relay is burnt out, a temperature controller is damaged, or a thermistor is damaged, the temperature gauge cannot control the temperature. The repair method is to replace the hot thermocouple, temperature controller, and heater.

● You can use an air compressor to clean up the remaining commodity debris at the feed and entrance of the small flow wrap machine, and the effect is also very good.

◆ flow wrap machine repair and maintenance

With the increase in automation level, the operation, repair, and daily maintenance of flow wrap machines have become more convenient and simple, this reduces the professional skills requirements for flow wrap machine operator. The quality of product packaging is directly related to the stability performance of temperature system, main engine speed precision, traceability system, etc. During the long-term use of flow wrap machine for sale, the following failures may occur:

1. There will be traces of burnt wrinkles on the seal;

2. The cutter will cut on the product;

3. The cutting position may deviate from the color mark.

4. The temperature control meter may not control the temperature.

5. Leakage or weak sealing may occur.

6. Poor heat sealing.

For the causes and solutions of these failures, we have made a more detailed introduction in the “Flow wrap machine troubleshooting” section of the article 700mm flow wrap machines. You can click to view. We have also introduced other possible situations in other articles, you can find them in our BLOG. We also welcome you to contact us for more information, such as flow wrap machine price, flow wrap machine image, horizontal flow wrap machine videos and so on, we will promptly answer your questions. We look forward to your inquiries!

+86 19112905173

+86 19112905173