flow wrap machine manual Chapter 6- maintenance of used flow wrap machine for sale

We are often asked by customers about the maintenance knowledge of flow wrap machines flow wrap machines , such as precautions for use and maintenance requirements. Maintenance and repair are effective ways to prolong the service life of machinery and reduce mechanical failures. As a replacement for manual labor, flow wrap machines should be treated as a helpful partner in production for companies. In addition to daily maintenance work, timely solutions to mechanical faults are also required. Regular maintenance and repair for used flow wrap machine for sale can effectively prevent issues such as excessive bearing wear and machine shutdowns.

To help users of packaging machines obtain more detailed knowledge about maintenance and repair for flow wrap machines, we have summarized the following points for reference, hoping to be helpful to our users.

◆ Maintenance for the mechanical part of flow wrap machine

1. Although flow wrap machine manufacturer has conducted testing and run-in at the factory for the new high speed flow wrap machine, users should also run it continuously for 24 hours at a mid-level speed (about 40 packages/minute) before running it at high speed.

2. After one month of operation for the new compact flow wrap machine, flow wrap machine operator should adjust the transmission chain and belt. And they should also be adjusted once every two months thereafter.

3. The horizontal sealing master-slave gears should be lubricated with grease once every two months of operation.

4. The vertical sealing cover plate should be cleaned twice a week, and lubricating oil should be added to the vertical sealing slide at the same time.

5. Please refer to the user manual of the continuously variable gearbox for the adjustment and use of the toothed chain of the chain-type continuously variable gearbox.

6. Flow wrap machine operator should regularly check whether fastened components are loose, and frequent lylubricate gears, racks, sprockets, chains, lead screws, and other components.

7. The used flow wrap machine should be regularly cleaned and wiped, including covers, work surfaces, and other external surfaces, to keep the machine clean.

◆ Maintenance of flow wrap machines electrical parts

1. Flow wrap machine operator should regularly check whether the wires are loose at each joint before turning on the machine.

2. Tiny particles such as dust may also affect the function of compact flow wrap machine. Photoelectric switches or proximity switches may experience false triggering when dust settles on the probes, so they should be regularly checked and cleaned.

3. Details are also a key focus of cleaning for used flow wrap machines. For example, regularly clean the carbon powder on the surface of the horizontal sealing electric slip ring with a soft cloth dipped in alcohol (note: be sure to cut off the power when cleaning).

4. Some parts of flow wrap machines cannot be changed at will, and non-professionals are not allowed to open the electrical parts. The parameters or programs of the frequency converter, microcomputer, and other control components have been set, so please do not change them at will. Otherwise, it will cause system disorder, resulting in the small flow wrap machine not working properly or even damaging the machine.

◆ Lubrication of flow wrap machine for sale

1. Rolling bearings are a part of high speed flow wrap machines that are subject to severe wear, so each rolling bearing should be lubricated with butter by a butter gun once every two months.

2. Different parts require different types of lubricating oil. For example, the shaft sleeve on the flow wrap machine film carrier roller and the shaft sleeve at the front sprocket of the feeding conveyor are suitable for adding 40# mechanical oil.

3.The lubrication of the continuously variable transmission should be carried out according to its instruction manual.

4. The meshing operation of gears is also very important, and each gear should be lubricated in a timely manner with 40# mechanical oil.

5. Lubrication of the chain is the most common. For relatively simple chain wheels and chains, mechanical oil with a kinematic viscosity greater than 40# should be dripped in a timely manner for lubrication.

6. The clutch is the key to starting the compact flow wrap machine, and the clutch part should be lubricated with oil or grease in a timely manner.

◆ Daily cleaning and maintenance

1) Before cleaning and wiping the used flow wrap machine, the power must be turned off to ensure the safety of the operator.

2) Wipe the work surface and outer surface of the flow wrap machine with a clean, moistened cloth.

3) Use compressed air to remove product debris from the feeding device, as well as the middle and end sealing areas.

4) Use a steel wire brush coated with lubricant to remove the film debris attached to the end sealing.

◆ Monthly inspection and maintenance

1)Oil lubrication should be applied to the meshing gears and chain links in the transmission system of the flow wrap machines, with the principle of light coating. But it is forbidden to oil lubricate the timing belts and conveyor flat belts on the flow wrap machines.

2) Oil lubrication should be applied to the end sealing bearing.

3) Check the tension of the chains and belts in the drive components, and tighten them if necessary.

4) Check the looseness of screws or nuts in each flow wrap machine parts, and tighten them if necessary.

5) Check the carbon deposit situation of the electrical brushes, and wipe if necessary.

◆ Half-year maintenance

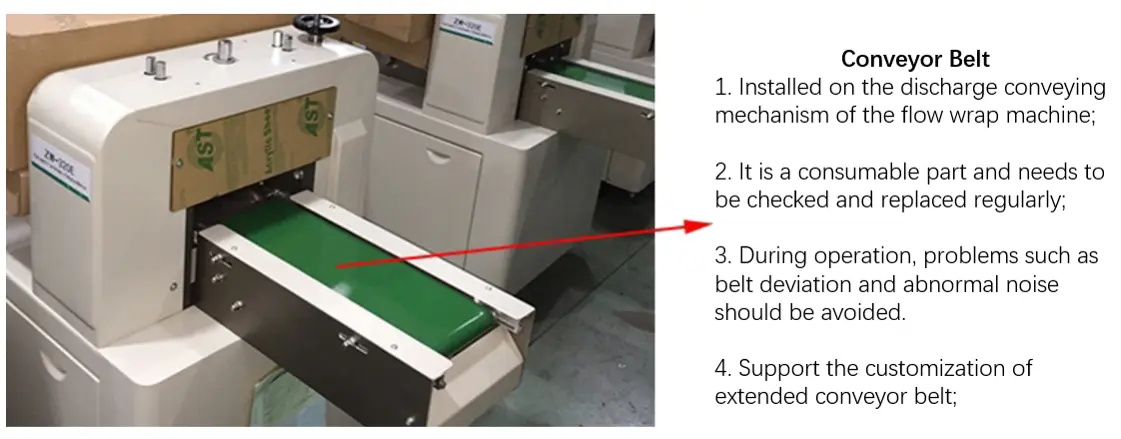

1) Check the wear and tear of the drive belts and conveyor flat belts on the flow wrap machines, and replace them if necessary.

2) Check the various vulnerable parts of the flow wrap machine, and replace them in a timely manner.

3) Check the wear and tear of all transmission parts, and replace them if necessary.

4) Check and tighten the electrical wiring, and use compressed air machine to clean the dust on all electrical components.

In addition to the maintenance knowledge mentioned above, we recommend that flow wrap machine operators and maintenance personnel try to understand the operating precautions of the flow wrap machines as well as some common flow wrap machine troubleshooting, so that they can quickly analyze the cause of problems and take corresponding solutions when issues arise. Even if they are unable to do flow wrap machine repair on their own, they can better communicate with our flow wrap machine engineers and improve the efficiency of fault resolution.

+86 19112905173

+86 19112905173