flow wrap machine manual Chapter 2 – machine introduction

In Chapter 1 of flow wrap machine manual, we introduced the safety precautions for flow wrap machine.This article is a machine introduction of flow wrap machine, including the application, structure, characteristic, and advantages of the flow wrap machine.

◆ 2.1 Application of flow wrap machines

Flow wrap machine is designed for flow packaging of solid objects, suitable for packaging various solid objects with regular shapes, such as food like biscuits, bread, moon cakes, candies, etc., as well as daily necessities, cosmetics, industrial parts, etc. For loose or individually separated objects, they must be placed in a box or tied together to form a whole before they can be packaged on this flow wrap machine, and the same principle applies to other non-solid objects to be packaged. Using flow wrap machine for packaging can have the functions of moisture-proof and light avoidance. It not only improves the packaging grade, but also saves labor costs, making it an excellent choice for manufacturers to achieve efficient packaging.

The horizontal flow wrap machine is divided into top film feeding flow wrap machine and bottom film feeding flow wrap machine for sale, and we have made related introductions in the article "Differences and applications between top film feeding and bottom film feeding flow wrap machines", so we will not describe it in detail here.

◆ 2.2 Advantages

Horizontal flow wrap machine can effectively ensure the packaging quality and obtain consistent packaging products of the required specifications according to the requirements of the packaged items, in terms of form and size, which cannot be guaranteed by manual packaging. Horizontal flow wrap machine can also reduce labor intensity and improve working conditions, which is favored by users of processing factories.

◆ 2.3. The characteristics of horizontal flow wrap machine

1) Compact and reasonable structure, stable and advanced performance, simple and easy to understand operation.

2) Double frequency converter control, bag length can be set and cut immediately without adjusting empty walk, one-step molding, saving time and film.

3) PLC control, touch screen human-machine interface, convenient and quick parameter setting.

4) Fault self-diagnosis function, clear display of faults, more user-friendly.

5) High-sensitivity photoelectric eye color mark tracking, making the sealing and cutting position more accurate.

6) The temperature is independently controlled by PID, adjustable, and better suited for various flow wrap machine film materials, improving the sealing quality.

7) It has positioning stop function, no sticking, and no film waste.

8) The transmission system is simple and clear, working more reliably and maintenance more convenient.

9) All controls are implemented by software, which facilitates function adjustment and technological upgrades, and can meet production needs in different periods.

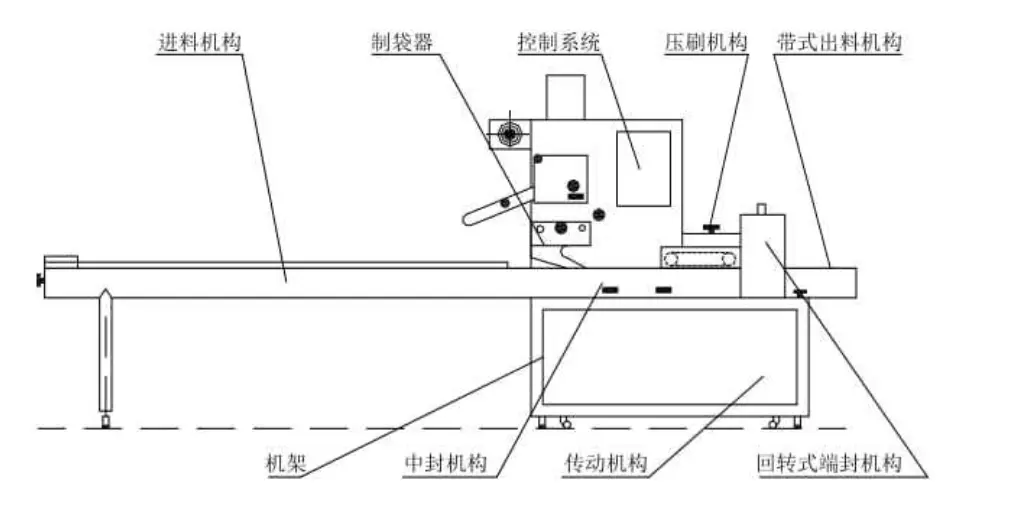

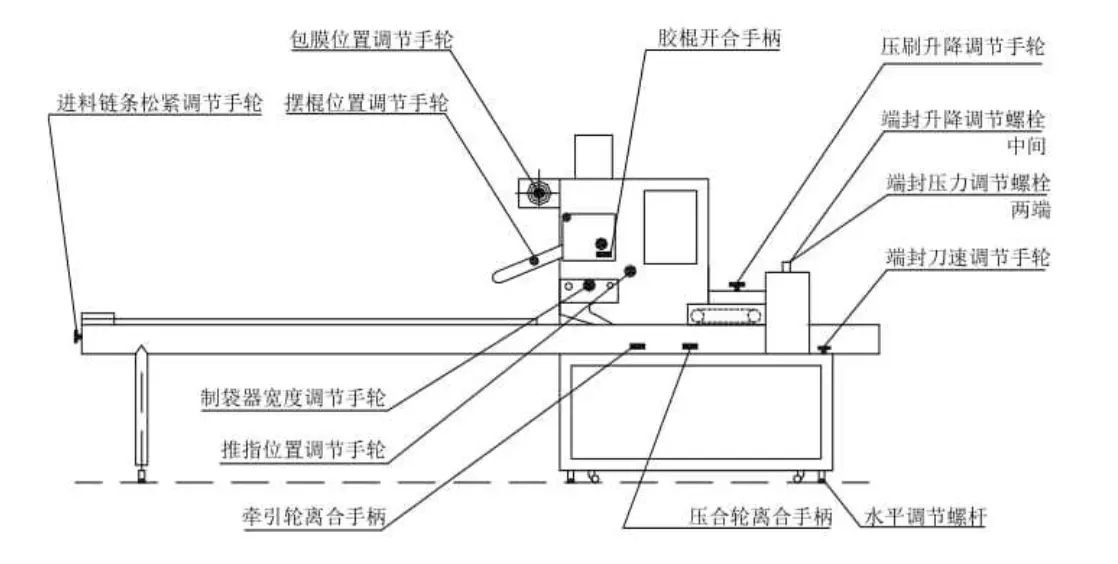

◆ 2.4 flow wrap machine Structure figure 1)

1. Film roll device---- used to install roll-shaped packaging film.

2. Packaging film feeding device---- used for pulling flow wrap machine film

3. Middle sealing device---- used to pull the flow wrap machine film, include film-pulling wheel and pressing wheel, and contains a hot-pressing plate device. After the packaging film enters the hot-pressing plate device and is heated, it is rolled and sealed by the pressing wheel.

4. Discharging device----used to convey the finished product after packaging.

5. Tail bracket device (feeding device, including feeding chain) ---- used to push the product into the bag.

6. Transmission device---- is used to connect the transmission between various parts, and is composed of chains, sprockets, and gears.

7. Electrical part (control system) ----flow wrap machine for sale control part.

8. Bag former---- to form the flat packaging film into bags.

9. End sealing device---- sealing and cutting.

10. Brush pressing mechanism.---Make those fixed materials which do not move with rolling to flow smoothly, and avoid cutting materials by mistake.

11. Base frame of the horizontal flow wrap machine.

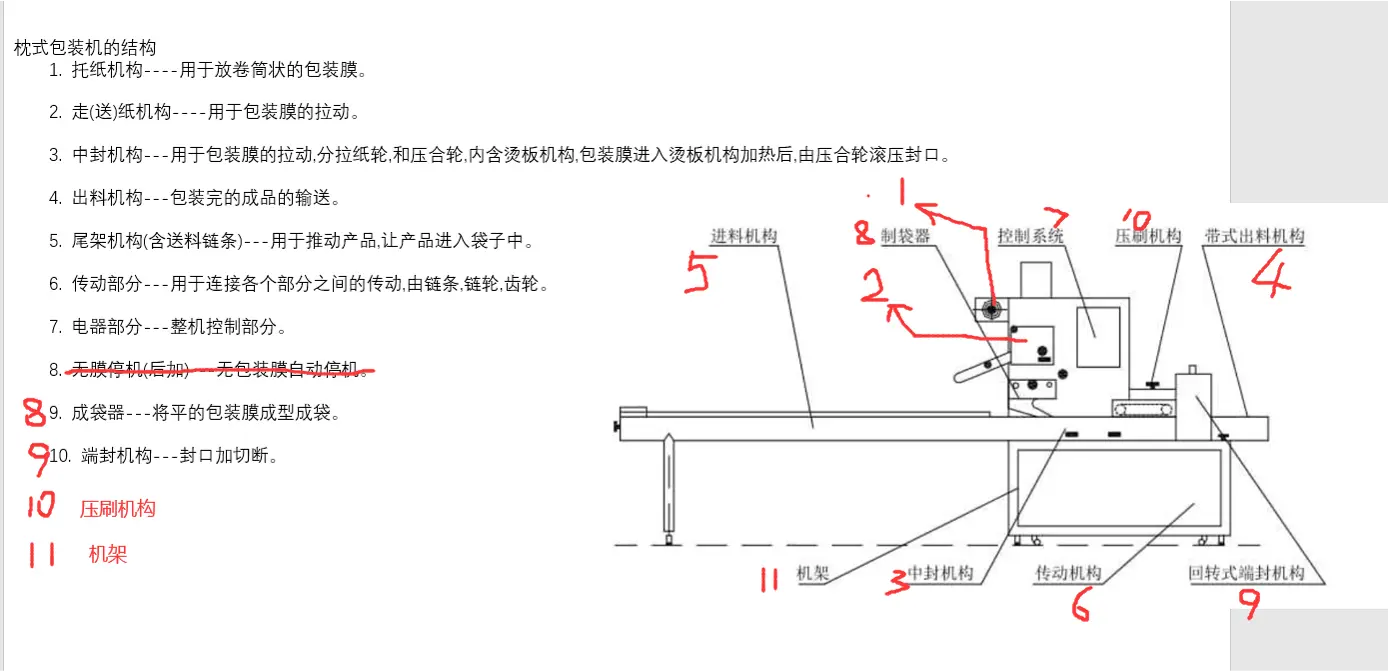

◆ 2.5 flow wrap machine adjustment components(figure 2)

1.进料链条松紧调节手轮 Feed chain tension adjustment hand wheel

2. 包膜位置调节手轮 flow wrap machine film position adjustment handwheel

3. 摆棍位置调节手轮 Swing stick position adjustment handwheel

4. 胶棍开合手柄 Glue stick opening and closing handle

5. 制袋器宽度调节手轮 Bag maker width adjustment handwheel

6. 推指位置调节手轮 Push finger position adjustment handwheel

7. 牵引轮离合手柄 Traction wheel clutch handle

8. 压合轮离合手柄 Press wheel clutch handle

9. 水平调节螺杆 Horizontal adjustment screw

10.端封刀速调节手轮 End sealing knife speed adjustment hand wheel

11. 端封压力调节螺栓(两端)End seal pressure adjustment bolts (both ends)

12. 端封升降调节螺栓(中间)End seal lifting adjustment bolt (middle)

13. 压刷升降调节手轮 Pressing brush lifting adjustment handwheel

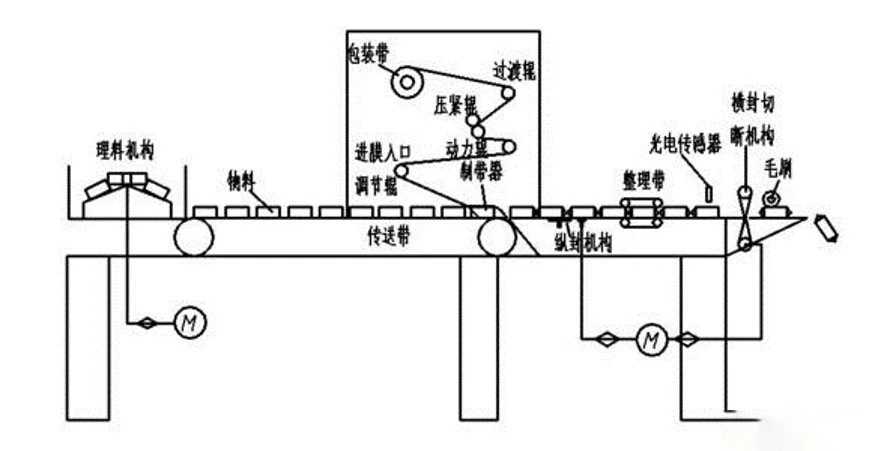

◆ 2.6 Working principle (igure 3)

In the following articles, we will continue to introduce knowledge about the installation, operation, machine adjustment, maintenance, troubleshooting and repair, and other aspects of flow wrap machines, so welcome to keep following our BLOG page.

+86 19112905173

+86 19112905173