flow wrap machine manual Chapter 5 - functional operation

The flow wrap machines has advanced packaging technology; sophisticated equipment manufacturing, powerful functions, and uses intelligent human-machine operating interface for easy operation. The flow wrap machine for sale has a very wide range of packaging applications and is deeply loved by manufacturers in various fields such as food, daily necessities, medicine, hardware, stationery, toys, and other industries. Understanding the structure of flow wrap machine for sale, and the flow wrap machine working principle, mastering the flow wrap machine mechanism adjustment, as well as the correct operation of the flow wrap machine, can help improve efficiency and ensure good packaging results. This article we will introduce the functional operation of the flow wrap machine.

5. The operation of flow wrap machines

(1) Safety inspection: Check and confirm that there is no debris on the conveyor belt, workbench, or end seal of the flow wrap machine, and no other person is operating the machine.

(2) Power on: Open the electric control box door lock, close the main circuit breaker, and observe whether the temperature controllers on the control panel of the compact flow wrap machine, power indicator lights, and human-machine interface are all displaying properly.

After completing the safety inspection and powering on, the small flow wrap machine needs to undergo the following operations.

5.1. The human-machine interface

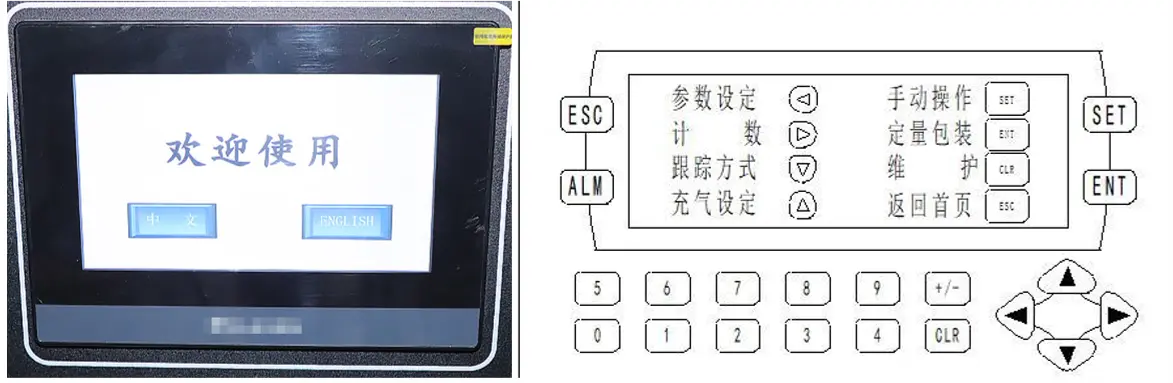

The setting of the main parameters of flow wrap machines is completed through the human-machine interface. After powering on, the human-machine interface displays the homepage first, the page as shown in the figure.

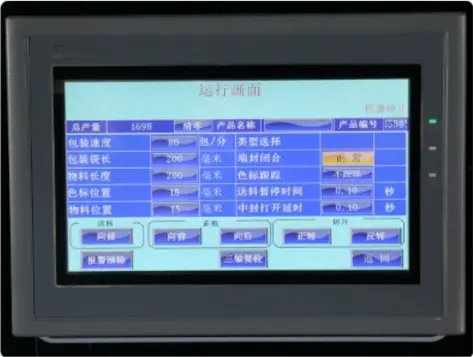

Press the (v) according to the screen instructions, and the human-machine interface will make a sound and enter the next interface (homepage), as shown in the figure.

◆ Parameter setting

According to the instructions of "human-machine interface homepage" instructions, press the (<=) to enter the "parameter setting" interface. Press the (↑) to return to the "human-machine interface homepage".

1) Setting "packaging speed"

According to the instructions on the "parameter setting" interface, press the to enter the "packaging speed" setting screen. Follow the instructions on the screen to enter the desired value. If the speed setting exceeds the rated range of the flow wrap machine for sale, an error prompt will be displayed and you will be required to reset the value until it is within the correct range.

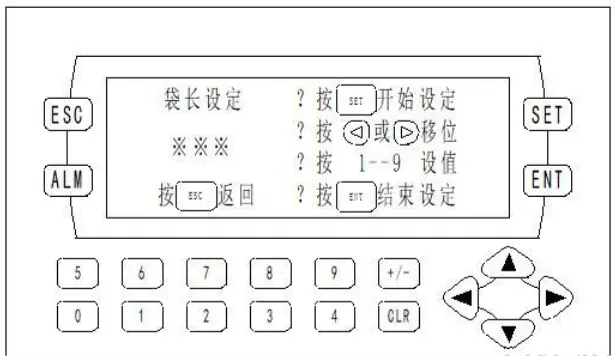

2) Setting "packaging bag length“

According to the instructions on the "parameter setting" interface, press the to enter the "packaging bag length" setting screen. Follow the instructions on the screen to enter the desired value. If the bag length setting exceeds the rated range of the cheap flow wrap machine, an error prompt will be displayed and you will be required to reset the value until it is within the correct range.

3) Setting "cutting position"

According to the instructions on the "parameter setting" interface, press the (∨) to enter the "cutting position" setting screen. Follow the instructions on the screen to enter the desired value. To confirm the entered value, first seal an empty bag with the cutting position value set to 0, measure the size L from the cut to the color mark, and then enter this test size value into the "cutting position" parameter.

◆ Counting

According to the instructions on the "human-machine interface homepage", press the (>) to enter the "counting" interface. This interface mainly records the cumulative working time, interface output and shift output of the flow wrap packing machine used, which is convenient for users to manage production. The shift output can be reset by pressing the (SET). Press the (↑) to return to the "human-machine interface homepage".

◆ Tracking mode

According to the instructions on the "human-machine interface homepage", press the (∨) to enter the "tracking mode" interface. Press the (↑) to return to the "human-machine interface homepage". Press the key for the machine to operate in "tracking cut" mode, and press the for the high speed flow wrap machine to operate in "fixed length cut" mode. For flow wrap machine film with color marks that means the product require tracking cut, select the "tracking cut" mode. Otherwise, select the "fixed length cut" mode.

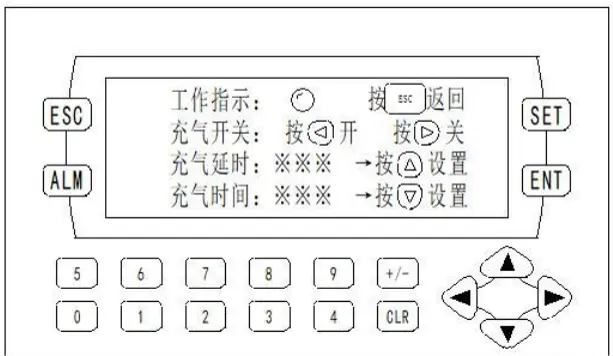

◆ Inflation setting (optional function)

According to the instructions on the "human-machine interface homepage", press the (∧) to enter the "inflation setting" interface, As shown in the figure. Press the (↑) to return to the "human-machine interface homepage".

1) Setting the "inflation delay"

According to the instructions on the "inflation setting" interface, press the (∧) to enter the "inflation delay" setting screen. Follow the instructions on the screen to enter the desired value. The size of the entered value should be determined based on the inflation effect. Press the (↑) to return to the "inflation setting" interface.

2) Setting the "inflation time"

According to the instructions on the "inflation setting" interface, press the (∨) to enter the "inflation time" setting screen. Follow the instructions on the screen to enter the desired value. The size of the entered value should be determined based on the inflation effect.

◆ Quantitative packaging

Flow wrap machines have a quantitative packaging function. That is, when the quantitative packaging function is turned on and the quantity is set, flow wrap machine will start packaging in the normal state. When the packaging quantity reaches the set packaging value, flow wrap machine will automatically stop. It is convenient to measure and process packaged products. After a mid-process shutdown, when restarting flow wrap machine, the quantitative packaging will start measuring from zero.

According to the instructions on the "human-machine interface homepage", press the (CLR) to enter the "quantitative packaging" interface. Press the (ESC) to return to the "human-machine interface homepage". Press the (<=), and the high speed flow wrap machine will be in the "quantitative packaging" mode. Press the (>), and the machine will be in the normal working mode.

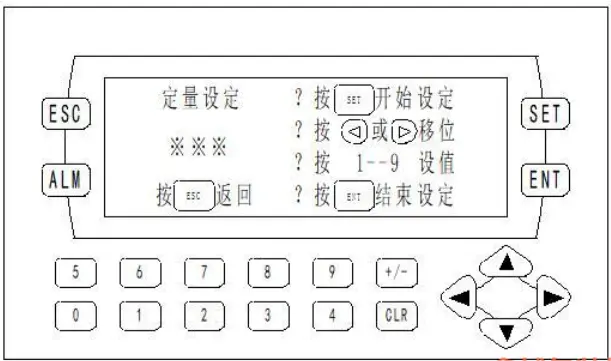

"Quantitative setting“

According to the instructions on the "quantitative packaging" interface, press the (∧) to enter the "quantitative setting" screen. Follow the instructions on the screen to enter the desired value, the size of which should be determined based on needs. Press the (ESC) to return to the "quantitative packaging" interface.

◆ Manual Operation:

a) Forward and backward movement of the film feeding system.

b) Forward and reverse rotation of the end sealing system.

c) Opening and closing of the middle sealing system.

5.2. Temperature Control

The flow wrap machine for sale has two sets of temperature control systems, which respectively control the "middle sealing temperature" and "end sealing temperature". The size of each set of temperature set values should be determined based on the speed of packaging, thickness of the packaging film, and ambient temperature. The most suitable set value should ensure that there is no leakage or wrinkling in the middle and end seals. For instructions on operating the temperature controller, please refer to the accompanying temperature controller manual.

5.3. Color-mark sensor

For products that require tracking during cutting, a color-mark sensor is necessary. After the flow wrap machine film is installed, adjust the position of the color-mark sensor so that the beam of light emitted by the sensor is aligned with the area where the color mark passes.

The sensitivity of the color-mark sensor is adjusted at the factory, but if further adjustments are required, refer to the accompanying sensor manual.

5.4. Start

1) INCHING

Press the “INCHING” (black) button, and the compact flow wrap machine will operate at a speed of 30 packages per minute during the pressing period. The machine stops immediately when the button is released.

2) Continuous operation

Pressing the “start” (green) button, the compact flow wrap machine will continuously operate at the set speed until the “stop” (red) or “emergency stop” button is pressed.

5.5. Stop

1) Regular stop

Press the “stop” (red) button, the flow wrap machine will stop at the horizontal position of the end sealing cutter.

2) Emergency stop

Press the “emergency stop” button, the small flow wrap machine will stop instantly. To restart the machine, the button must be reset first.

If you want more knowledge about flow wrap machine, such as Differences and applications between top film feeding and bottom film feeding flow wrap machines, you can cleck our blog for more information.

+86 19112905173

+86 19112905173