Liquid filling machine semi automatic

◆ Liquid filling machine definition

A liquid filling machine is a type of industrial equipment used to accurately and efficiently fill containers with liquid substances. It typically consist of a reservoir or hopper for holding the liquid, one or more liquid filling machine nozzle, a filling mechanism such as a pump or piston, and controls for adjusting the fill volume and speed, automates the process of measuring and dispensing liquids into bottles, jars, or other containers. Liquid filling machine is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing to streamline the packaging process and ensure precise and consistent filling of liquid products.

This article introduces a liquid filling machine semi automatic, "semi-automatic" means that the liquid filling machine can automatically carry out quantification and filling, but it requires manual placement and removal of the filling container, and the sealing of the container requires additional machinery and equipment. This liquid filling machine semi automatic also is a benchtop liquid filling machine designed to be placed on a workbench or tabletop, it is a compact and multifunctional device, providing convenience and ease of use. This liquid filling machine semi automatic is a single nozzle liquid filling machine, meaning it has only one liquid filling machine nozzle and can fill only one container at a time.

You can watch our liquid filling machine video to get a clearer understanding of how our liquid filling machine semi automatic works.

◆ Technical Parameters

| Product name | liquid filling machine semi automatic |

|---|---|

| Model No.: | YS-1000 |

| Machine Type: | Liquid Filling Machine |

| Applicable Industries: | Food & Beverage Factory, Restaurant, Home Use, Food Shop, Other, |

| Application: | Food, Beverage, Commodity |

| Packaging Type: | CANS, Bottles, Bags, Pouch, Other |

| Packaging Material: | Plastic, Metal, Glass |

| Filling Material: | Honey, Milk, Water, Oil, Juice and so on. |

| Hopper capacity: | 30L (customized) |

| Filling range: | 80-1100ml |

| Optimal Filling range: | 100-1000ml |

| Optional Filling range: | 10-100ml; 30-300ml; 50-500ml; 100-1000ml;300-3000ml,1000-5000ml, etc. |

| Filling Accuracy: | ±1% |

| Automatic Grade: | Semi-automatic |

| Driven Type: | Pneumatic and electric |

| Rated Air Pressure: | 0.4-0.6MPa |

| Voltage: | 220V/110V 50Hz/60Hz |

| Power: | 10W |

| Dimension(L*W*H): | 113*32*30cm |

| Weight: | 27.6 KG |

◆ Liquid filling machine design

• Food-grade Materials;

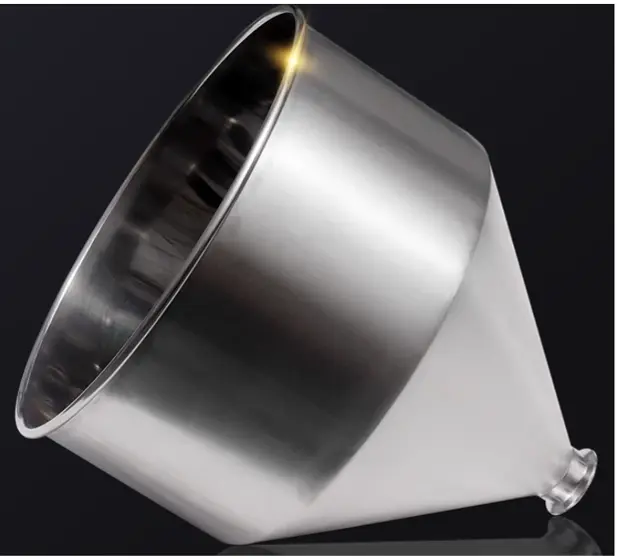

Big stainless steel hopper, and the liquid filling machine parts that comes into contact with the liquid or ointment to be filled are made of 304 stainless steel, which has corrosion-resistant, wear-resistant, safe and healthy characteristics.

• Convenient Adjustment of Filling Volume;

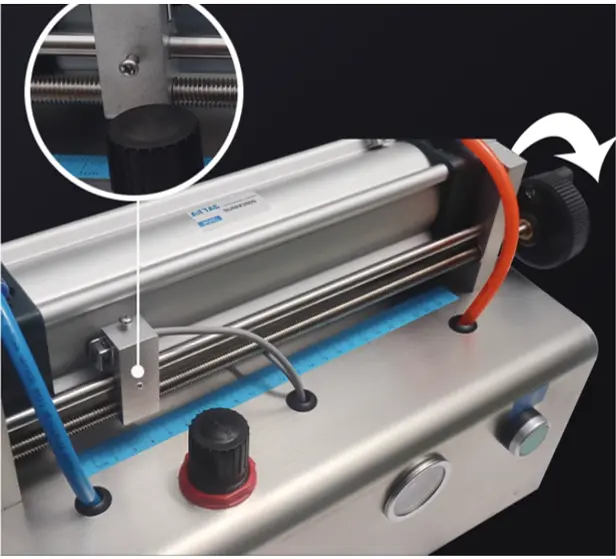

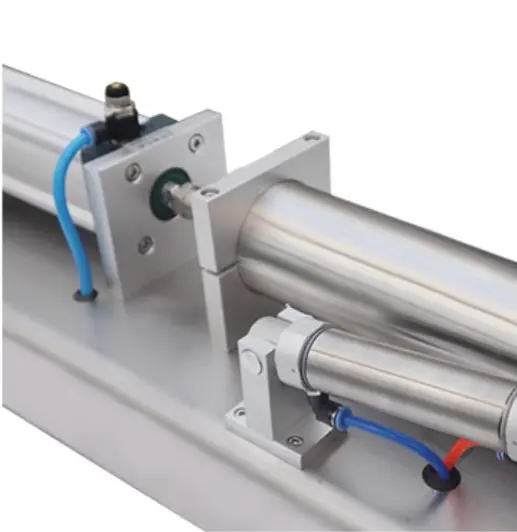

Our liquid filling machine semi automatic uses high-quality cylinder with good sealing, stable and corrosion-resistant air pressure, can accurately control every filling, ensuring accurate measurement.

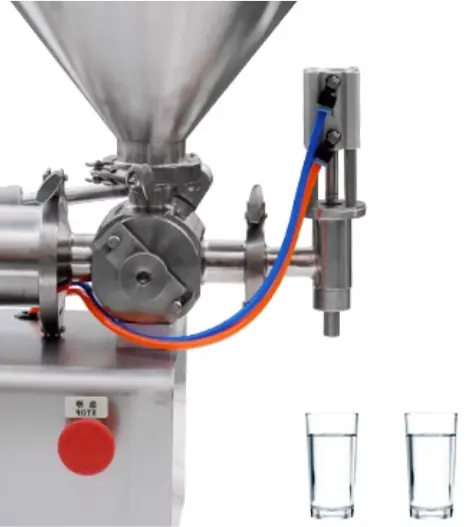

• Stainless Steel Discharge Nozzle;

The liquid filling machine nozzle is made of high-quality steel, stable and durable, with accurate filling performance and long service life, equipped with a high-precision anti-drip filling system.

• High-quality Piston;

Our Liquid filling machine nozzle adopts a PTFE piston, which is wear-resistant, has good sealing performance, and is durable

• Filling Adjustment Lever;

Rotates to adjust the filling amount, allowing for easy adjustment of the quantity, and convenient operation.

• Emergency Stop Switch;

An emergency stop button that can immediately stop the liquid filling machine semi automatic's operation.

• Manual/Automatic mode, Rotary switch;

Manual mode: The liquid filling machine semi automatic equipped with a foot switch, press once to discharge once;

Automatic mode: Interval time can be set, allowing for complete control over the filling process;

◆ Liquid filling machine operation

The working principle of a liquid filling machine semi automatic involves the combination of manual and automated processes. Here is a general overview of the liquid filling machine operation:

Step 1. Machine Preparation: Connect the liquid filling machine semi automatic to the power source and ensure all components are securely assembled. If necessary, clean and sanitize the liquid filling machine and its parts.

Step 2. Calibration: Some liquid filling machine may require calibration to ensure accurate filling volumes. Follow the instructions in the liquid filling machine manual to calibrate the machine appropriately.

Step 3. Preparation of Material to be Packaged: The operator prepares the liquid to be filled, making sure it is in the appropriate reservoir or container within the liquid filling machine.

Step 4. Setting Filling Parameters: The operator adjusts the filling volume, speed, filling time, and other settings on the control panel of the liquid filling machine based on the specific requirements of the product.

Step 5. Container Placement: Place the containers to be filled on the conveyor system or manually position them under the liquid filling machine nozzle.

Step 6. Filling Process: Initiate the filling process either manually or through an automated control system. In a liquid filling machine semi automatic, this is typically done by activating a pump or piston mechanism. The liquid filling machine semi automatic dispenses the liquid product into the containers through the liquid filling machine nozzle using gravity or pressure systems.

Step 7. Accuracy Check: Regularly inspect the filled containers to ensure the desired filling volume is consistently achieved. Make adjustments if necessary.

Step 8. Container Removal: Once the containers are adequately filled, the operator removes them from the filling platform or conveyor system.

Step 9. Repeat the Process: The operator repeats the process for the next container, manually placing it in position and initiating the filling cycle once again.

Step 10. Liquid Filling Machine Cleaning and Maintenance: After completing the filling tasks, thoroughly clean the liquid filling machine, especially the thick liquid filling machine, to prevent contamination and maintain its performance. Please follow the maintenance and routine inspection guidelines provided by the liquid filling machine manufacturer.

Please note that specific operational procedures may vary depending on the liquid filling machine manufacturer and model. Be sure to refer to the liquid filling machine user manual provided by the manufacturer for detailed instructions pertaining to your liquid filling machine.

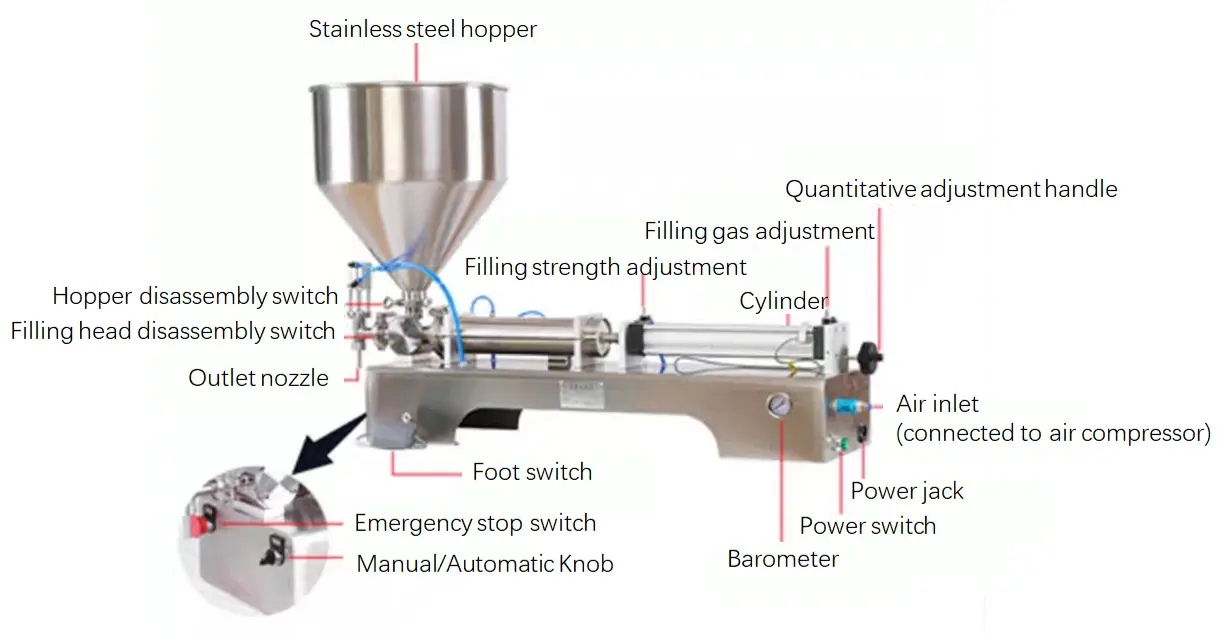

◆ Liquid filling machine diagram

◆ Application of liquid filling machine

In the selection of liquid filling machines, the viscosity of the liquid to be filled is an important factor to be considered. Different liquid viscosities may require different liquid filling machines to handle. Our liquid filling machine semi automatic has a wide range of applications. It is not only suitable for filling low-viscosity liquids but also functions as a thick liquid filling machine, also known as a viscous liquid filling machine. It can handle high-viscosity or thick liquids such as sauces, pastes, creams, gels, or oils, among others.

● Food and Beverage Industry: This liquid filling machine semi automatic is widely used in the food and beverage industry for filling water, fruit juice, milk, soda water, edible oil, sauce and other liquids as well as sauces, seasonings, condiments, jams , jelly, syrup, cream, honey and other viscous foods. These machines ensure accurate and efficient filling of bottles, cans, bags or other containers.

● Cosmetics and personal care industry: This thick liquid filling machine is widely used in cosmetics and personal care industry for filling various beauty and personal care products, such as lotion, cream, gel, essence, shampoo, Hair conditioner, perfume and liquid soap, body cream and other beauty and skin care products. These machines provide precise filling control and maintain product texture and viscosity integrity.

● Pharmaceutical and Healthcare Industry: This thick liquid filling machine plays a vital role in the pharmaceutical and healthcare industry for filling medicines, syrups, tinctures, ointments, creams, gels and other medicines. These machines meet stringent requirements for hygiene, precision and dosing accuracy.

● Chemical and Industrial Applications: This viscous liquid filling machine is applied in chemical and industrial fields for filling various liquids including solvents, detergents, lubricants, adhesives, paints, coatings and industrial chemicals .

● Automotive and Manufacturing: This viscous liquid filling machine is used in automotive and manufacturing for filling engine oil, brake fluid, coolant, lubricant, sealant and more.

● Household and cleaning products: This liquid filling machine semi automatic is used for filling household and cleaning products, such as detergent, fabric softener, dishwashing liquid, disinfectant and other cleaning solutions, etc.

These are just a few examples of the diverse applications of viscous liquid filling machines. Welcome to consult us about more applications of packaging machines through WHATSAPP.

Warmy Reminder:

In addition to the single nozzle liquid filling machine mentioned in the article, there is another model called “semi automatic liquid filling machine two head”. It has two liquid filling machine nozzles, allowing simultaneous filling of two containers and improving production efficiency. Feel free to contact us for further consultation.

Please note that this liquid filling machine semi automatic needs to be used with an air compressor. The liquid filling machine equipment does not include an air compressor, which needs to be purchased separately by the customer.

◆ Extended knowledge – liquid filling machine types

There are various ways to classify liquid filling machines, so there are many different liquid filling machine types. For example:

1. According to the level of automation of the liquid filling machine, it can be divided into hand operated liquid filling machine, liquid filling machine semi automatic, and liquid filling machine automatic.

2. According to the structure of the liquid filling machine, it can be divided into linear liquid filling machine and rotary liquid filling machine. The linear liquid filling machine has a linear conveyor system that allows containers to move in a straight line during the filling process. The rotary liquid filling machine uses a rotating mechanism to fill containers with liquid, and it consists of a turntable or conveyor belt with multiple stations, containers are placed on the turntable and move through different stations as it rotates.

3. According to the number of liquid filling machine heads, liquid filling machines can be classified as single nozzle liquid filling machine and multi-head liquid filling machines (such as liquid filling machine two head, liquid filling machine 8 heads, etc.). The more liquid filling machine heads there are, the more containers can be filled simultaneously, but the liquid filling machine price will also be higher. These multi-head liquid filling machines are usually equipped with bottle sorting machines, capping machines, labeling machines, etc., forming a production line to significantly improve production efficiency.

4. According to the filling principles of the liquid filling machine, it can be divided into vacuum liquid filling machine, atmospheric pressure filling machine, back pressure filling machine, negative pressure filling machine, and so on.

There are other classification methods for liquid filling machines, and is hard to list them one by one. In general, different liquid filling machine types are suitable for different production needs. While providing convenience to users, it also brings them confusion in choosing the right machine model. We recommend that users consider their actual production needs when selecting a liquid filling machine. Please comprehensively considering factors such as the nature of the material to be filled, the type of containers, production scale, and the affordable price of the liquid filling machine before making a prudent decision.

If you have any concerns in this regard, please feel free to contact us via WhatsApp for specific consultation. We are a professional liquid filling machine manufacturer and exporter with extensive experience. We believe that we can help you find the appropriate liquid filling machine.

+86 19112905173

+86 19112905173