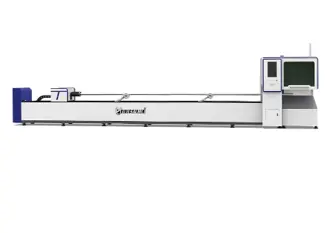

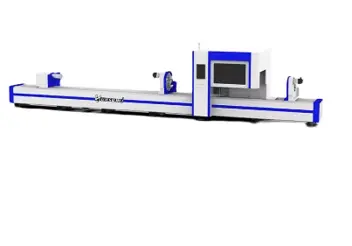

CNC laser tube cutter

● CNC laser tube cutter definition

The CNC laser tube cutter is also called fiber laser tube cutter machine and is a cut equipment with high accuracy by using laser technology. It can cut various metal tubes, such as stainless steel, aluminum alloy, copper, etc, and also can cut various shapes of tubes, such as round tubes, square tubes, and oval tubes to meet different requirements of industries. The laser tube cutter consists of laser generator, control drive system, pipe laser cutting machine, light guide external optical path system, cutting head, workbench, guide rail, pneumatic rotating fixture, mobile rotating fixture, automatic loading and unloading device, chiller, cold dryer, regulated power supply, etc. It has the advantages of fast cutting, accurate cutting, and high effectiveness. The tube laser cutter has wide applications in metal process industries, such as Automobile manufacturing, aerospace, architectural decoration, etc.

● Our tube laser cutter for sale

1000W laser tube cutter

1500W pipe laser cutter

2000W fiber laser tube cutter machine

3000W CNC laser tube cutterlaser

● Tube laser cutter working principle

The working principle of tube laser cutter is to adopt the laser beam to cut tubes. The laser beam is focused through the optical system to make a high energy density light spot. The control system controls the movement of the light spot to achieve the cutting of the tubes. The laser cutter tube can adjust the focal length and power of the laser beam focal according to different tube diameters and cutting requirements to achieve a good cutting effect.

● Advantage of tube laser cutter

The metal tube laser cutter main cut the stander workpiece and nonstandard workpiece, the stander workpiece including round tubes, square tubes, and oval tubes. The nonstandard includes angle steel, channel steel, I-beam, composite profile, etc. Compared with traditional process methods, The laser cutter for metal tube has the following advantages.

1. The CNC tube laser cutter has a high cutting accuracy and the cutting accuracy is ±0.03mm.

2. The cutting surface is smooth, flat, and burr-free by using the metal tube pipe laser cutter.

3. The tube laser cutter machine adopts non-contact cutting, the laser cutting is a hot cutting in a small area and the hot influence area is small. So, the cutting products are basically free of deformation.

4. The tube laser cutter machine has high cutting effectiveness and the cutting fast is 10m/min. In addition, it has an automatic feed function and can batch cutting over a long period of time.

5. The CNC tube laser cutter adopts the smart control system, the operation interface is clear and operation is easy, we just need to import corresponding drawings and this machine will start cutting.

The advantage of the laser cutter for metal tube is to replace the punching, drilling, and sawing process and the finished product does not require polishing. The laser tube cutter machine can achieve various shapes cutting, and drilling. It can reduce the waste of material, reduce the labor cost, and improve working effectiveness.

● Fiber laser tube cutter process

Suitable tubes: round tubes, square tubes, oval tubes, etc.

Suitable materials: carbon steel, stainless steel, galvanized, alloy, etc.

Suitable process: cutting, punching, grooving, arcs, graphics, text, etc.

● Industrial laser tube cutter applications

The industrial laser tube cutter uses laser technology to cut tubes. It adopts CNC technology and can achieve high accuracy and high-speed cutting. In addition, it will not cause tool wear problems, so, our product has high stability and reliability. The china metal tube laser cutter has wide applications in processing fields of metal, non-metallic, and other special materials, such as construction, automobile manufacturing, pipe processing, electronic industry, communications, medical equipment, and environmental protection.

1. Construction industry: The construction industry needs large various metal tubes, such as steel pipes, stainless steel pipes, aluminum alloy pipes, etc. So, the construction industry is one of the main application scenarios of steel tube laser cutter. The steel tube laser cutter can cut these tubes with accuracy to achieve the production of doors, windows, stair handrails, railings, etc.

2. Furniture manufacturing industry: The metal tube fiber laser cutter has wide applications in the furniture manufacturing industry. For example, for the tubes of the chairs, and tables, the traditional process method needs to use different tools to cut and punch holes, waste a large time and labor cost, and difficult to guarantee quality. The metal tube fiber laser cutter can achieve one-time accurate cutting and improve the working effectiveness and quality.

3. Tubes process: The fiber laser cutter for tube is always used to process the tubes, as for the tube process, it needs to ensure the roundness and straightness of the tubes to prevent the quality problems of the cracks. The fiber laser cutter for tube has high stability and accuracy to meet the requirements of the tube process.

4. Electronics industry: In the electronics industry, the CNC laser tube cutter was used in the process of high-precision parts, such as LED lamp tubes, electronic component assembly, electronic strips, etc. It has the advantages of high efficiency, fast, and high accuracy.

● Our advantages

1. Professional china metal tube fiber laser cutter factory

As professional laser plate tube cutter machine factories, we have more than ten years of experience in research and development, procurement, production, sales, and service to provide good quality products for customers. We also provide most ecenomic laser tube cutter and customized metal tube pipe laser cutter services according to the needs of the customers.

2. Complete product specifications

The tube laser cutter:3d laser cutter for irregular tube,steel tube laser cutter,vortex tube laser cutter, aluminum tube laser tube cutter,laser cutter with ceramic tube,plastic tube laser cutter, etc.

We mainly produce various metal process machines, except the laser cutter tube, we also produce pipe bending machines, laser cutting machines, milling machines, bending machines, and shearing machines. We have complete product specifications to meet the different needs of customers. If you are interested in our products, please contact us by WhatsApp.

3. Modern manufacturing base

Our factory has a modern manufacturing base and more than 600 units of produce equipment, including machining center, large floor hammer, large gantry planer, gantry broaching machine, external cylindrical grinder, CNC shearing machine, CNC bending machine, CNC flame cutting machine, laser cutting machine, multi-functional rolling mill line, column punching and rolling line, beam rolling mill line, beam support rolling mill, electrostatic powder coating production line, etc. We have a perfect quality management system to ensure the parts quality of the laser tube cutter for sale. We also have the perfect production system to provide good metal tube laser cutter price for customers.

4. Good pre-sales and after-sales services

We have rich professional technology and good equipment. We have a professional team to provide one-on-one services and purchase laser tube cutter machine plan. As for the problems of the metal tube fiber laser cutter for sale, we provide different language technicians to help customers deal with problems, such as Spanish technicians, English technicians, French technicians, etc.

+86 19112905173

+86 19112905173