vertical colloid mill

◆ Vertical colloid mill introduction

This article we will introduce a vertical colloid mill to our customers. All the colloid mill parts are installed vertically, so it has a compact colloid mill construction, only take small space, and with low colloid mill price. Due to these advantages, vertical colloid mill is very suitable for medium-sized enterprises and small production scale users. Except the motor, other colloid mill parts all use stainless steel as colloid mill material, which is environmentally friendly and hygienic, and is especially suitable for the food and beverage industry, usually be used as colloid mill coffee, colloid mill mayonnaise, colloid mill peanut butter. In addition, the colloid mills usage is very wide and can also be used as colloid mill pharmaceutical, colloid mill emulsion, colloidal suspension, etc., for ultra-fine grinding processes in the pharmaceutical, chemical industry, cosmetics industry. Let’s see more information about colloid mill for sale so that you can have a clearer understanding of the colloid mill working.

◆ More introduction of colloid mill machine

● colloid mill machine definition

Colloid mill machine, also known as colloid mill grinder or colloid mill mixer, is a type of milling equipment used for processing various substances into fine particles or emulsions.

● uses of colloid mill

The main colloid mill function is to reduce the particle size and achieve uniform and stable mixing of liquid or semi-liquid components. The colloid mill grinder has the functions of a variety machines such as mixers, pulverizers, and refiners, the colloid mill working efficiency is even two to five times of these above machines, and can achieve ultra-fine grinding effect. Because of the strong colloid mill function, colloid mills are commonly used in industries such as food, pharmaceuticals, cosmetics, and chemicals for applications such as grinding, homogenizing, emulsifying, and dispersing.

● how does colloid mill works

If want to know how colloid mill works, we should see colloid mill machine working principle first. The main composition of colloid mill is high-speed colloid mill rotor stator. Both the colloid mill rotor stator are conical and have closely spaced grooves. During the colloid mill working, the stator is fixed, the rotor rotates at high speed to achieve the purpose of colloid mill particle size reduction. This is the working principle of colloid mill. So how does colloid mill works? First, feed the material to be processed into the hopper of the colloid mill homogenizer; when it goes through the gap between the colloid mill rotor stator, it will be it will be affected by the strong shearing, mixing and grinding forces that caused by the relative motion of the stator and rotor. This colloid mill process allows for the reduction of particle size and the creation of stable colloidal suspensions or emulsions, to achieve the purpose of colloid milling.

◆ Colloid mill specifications

In order to meet the requirements of users with different scales, we have many colloid mill types and complete colloid mill specifications. The following are the commonly used vertical colloid mill specifications. In addition, we can also customize special colloid mill specifications according to user needs.

| colloid mill specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model(F Split) | Motor power(kw) | Colloid mill speed(r/min) | Tolva capacity (customizable) | Processing fineness(μm) | Colloid mill capacity(t/h) | Grinding disc diameter(mm) | Cooling water pipe(mm) | Outlet(mm) | Inlet(mm) | Weight(kg) | Dimension for reference(L*W*H) |

| JML-50 | 1.1/1.5kw | 2900 | 6L | 2-40 | 0.01-0.1 | 50 | 10 | 20 | 30 | 48 | 270*500*700 |

| JML-65 | 1.5kw-220v | 2900 | 6L | 2-40 | 0.02-0.5 | 65 | 10 | 20 | 30 | 50 | 270*500*700 |

| JML-80 | 3.0kw-380v | 2900 | 10L | 2-40 | 0.3-1 | 80 | 12 | 25 | 48 | 85 | 350*570*920 |

| JML-100 | 5.5kw-380v | 2900 | 15L | 2-40 | 0.5-2 | 100 | 12 | 25 | 66 | 145 | 390*645*980 |

| JML-120 | 7.5kw-380v | 2900 | 15L | 2-40 | 0.5-3 | 120 | 12 | 32 | 66 | 150 | 390*645*980 |

| JML-140 | 7.5kw-380v | 2900 | 15L | 2-40 | 0.5-4 | 140 | 12 | 32 | 66 | 180 | 390*750*1020 |

Note:

1. In the colloid mill specifications table above, the "L" in the model "JML" refers to vertical colloid mill. The motor and other colloid mill parts of the vertical colloid mill are vertically distributed, making the colloid mill construction very compact and simple.

2. We may make some upgrades that do not affect the basic colloid mill construction and colloid mill properties. We won’t notify individually of this.

3. The colloid mill capacity varies according to the different properties of the processed materials, so the colloid mill specifications in the above table are for reference only.

4. “JM-65” and “JM-50” colloid mill types can be equipped with 220V motors and are generally used at home and small shops, or be used as a laboratory colloid mill to develop more colloid mill functions and test how colloid mill works.

5. The motors of colloid mill type “JM-80” (3kw) and above are all 380V. They are used as industrial colloid mill machines and have bigger colloid mill capacity. They are suitable for large-scale and batch production.

◆ Uses of colloid mill

This vertical colloid mill is our new designed high-shear colloid mill grinder. The colloid mill material is forged from stainless steel and complies with national sanitary requirements. Colloid mill machine has a wide range of applications and is often used as an industrial colloid mill machine. It is suitable for the ultra-fine grinding processes in the food and beverage industry, chemical industry, cosmetics industry, etc.

1. Food industry: The colloid milling machine can use for processing food products such as dairy products, chocolate, bean paste, jam, peanut butter, cream drinks, etc.

2. Chemical industry: The colloid mill homogenizer can be used to grind chemical products such as pigments, lubricants, spices, dyes, asphalt, rubber, catalysts, paints and coatings, etc.

3. Biological industry: In this industry, the colloid mill grinder is great helpful to production of fish oil, queen bee, pollen, etc.

4. Daily chemicals: [Homogenizer colloid mill can use for the processing of shoe polish, toothpaste, cosmetics, balm, soap, detergent, etc.

5. Other industries: colloid mills also can use for construction industry, paper industry, plastic industry, battery industry, etc.

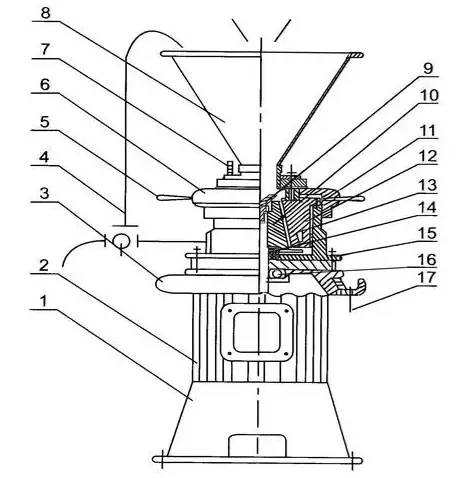

◆ Colloid mill diagram

1. Base

2. Motor

3. End cover

4. Circulation pipe

5. Adjustment disk handle

6. Adjustment disk

7. Cooling water pipe joint

8. Hopper

9. Rotary blade knife (fastening thread of moving grinding disc)

10. Rotor

11. Positioning screw

12. Stator

13. Cooling channel

14. Mechanical seal components

15. Shell

16. Spindle bearings

17. Leaking pipe joint

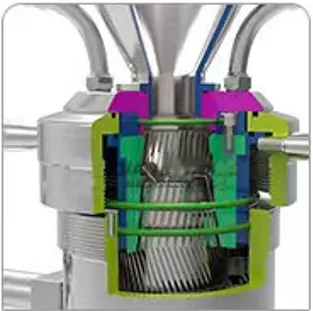

◆ Colloid mill details

-

1. The colloid mill material is stainless steel 304/316, strong and durable, does not rust, does not corrode, and is clean and hygienic;

-

2. High-precision stainless steel colloid mill rotor stator, tight gear structure, can crush materials instantly;

-

3. The colloid mill particle size reduction level (the thickness of material grinding) can be adjusted according to production needs. Adjust it clockwise to make it finer and counterclockwise to make it thicker.

-

4. The vertical colloid mill has a beautiful appereance and good sealing performance, also the colloid mill properties is very stable, and the colloid mill operation is easy and convenient

-

5. The vertical colloid mill adopts a quick-installation joints, which are easy to install and disassemble for cleaning;

-

6. The colloid mill parts-motor is high power, large torque, low temperature rise, and small vibration;

-

7. This vertical colloid mill adopts a double reinforced base to provide excellent stability and ensure the stable colloid mill working;

◆ Installation process of vertical colloid mill

Here we will briefly introduce the installation process of vertical colloid mill, for more detailed colloid milling machine installation, operation and maintenance knowledge,you can refer to our colloid mill manual

1. Prepare all the colloid mill spare parts;

2. Place the black sealing ring first and then the hopper of the homogenizer colloid mill;

3. Place the white sealing ring and three-way ball valve, and tighten them with clamps;

4. Place another white sealing ring on the three-way ball valve, and then put the colloid milling circulation pipe, then tighten them with clamps;

5. Put a white sealing ring to the outside of the three-way ball valve, then place the elbow and tighten it with clamps;

6. Finished the installation of colloid mill parts, and formed into a colloid mill unit.

◆ Other more colloid mill types

This vertical colloid mill is a circulating tube style, it is suitable for materials with low viscosity that require circulation and backflow grinding, such as soy milk, mung bean drinks, etc. In addition, we have another colloid mill type with square outlet port, which is suitable for materials with medium or high concentration that no need backflow grinding, such as peanut butter, chili sauce, etc.; there are also ordinary colloid mill types (means the outer body of the colloid mill machine is spray-painted and not covered with stainless steel shell) and split colloid mill types can be selected to meet the production needs of different users.

+86 19112905173

+86 19112905173