Zipper pouch packing machine

zipper pouch packing machine price: USD 33000 – 38000

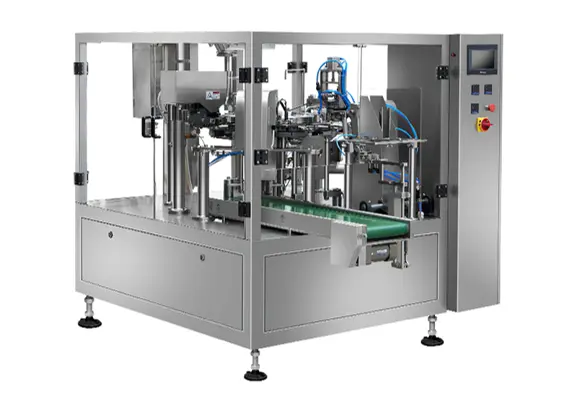

◆ Automatic pouch packing machine description

The fully automatic zipper pouch packing machine also known as automatic stand up pouch packing machine, it is one of the automatic premade pouch packaging machine. This fully automatic pouch packing machine replaces manual packing and realizes packing automation for the pharmaceutical, food, chemical and other industries large, small and medium-sized enterprises.

The operator only needs to put the finished packaging bags (hundreds of bags) in the bag storage part of the zippe premade pouch packing machine at one time, and the manipulator of the automatic zipper pouch packing machine will automatically take the bags, print the date, open the bags, and send signals to the metering device to measure and filling, sealing, output.

Customers can also add detailed functions such as door opening emergency stop, automatic card input, and abnormal discharge according to product packaging requirements. The whole process of packaging does not require manual work, which effectively improves production efficiency for your company, saves labor costs and management costs, and greatly reduces costs.

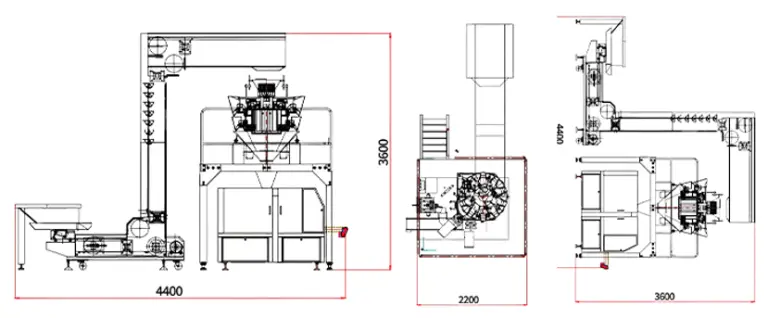

◆Product parameters

| Model | YS-200V | YS250V | YS-300V |

|---|---|---|---|

| Application bag type | Stand-up pouch, zipper bag, special-shaped bag, four-side seal bag, paper bag, eight-side seal bag, etc. | Stand-up pouch, zipper bag, special-shaped bag, four-side seal bag, paper bag, eight-side seal bag, etc. | Stand-up pouch, zipper bag, special-shaped bag, four-side seal bag, paper bag, eight-side seal bag, etc. |

| Function | Automatic metering and packaging of granules, powders, liquids, etc. | Automatic metering and packaging of granules, powders, liquids, etc. | Automatic metering and packaging of granules, powders, liquids, etc. |

| Packing speed | 1-60 bags/min (speed depends on material characteristics and filling weight) | 1-60 bags/min (speed depends on material characteristics and filling weight) | 1-60 bags/min (speed depends on material characteristics and filling weight) |

| Bag size | L≤360mm, W≤200mm | L≤360mm, W: 130-250mm | L≤460mm, W:150-300mm |

| Air consumption | 6Kg/m, 0.4m3/min | 6Kg/m,0.4m3/min | 6Kg/m, 0.4m3/min |

| Power | 380V/8.5KW | 380V/8.5KW | 380V/8.5KW |

| Main body weight | About 700KG | About 700KG | About 700KG |

| Dimensions | 1950*1400*1520 (mm) | 1950*1400*1520 (mm) | 2100*1500*1520 (mm) |

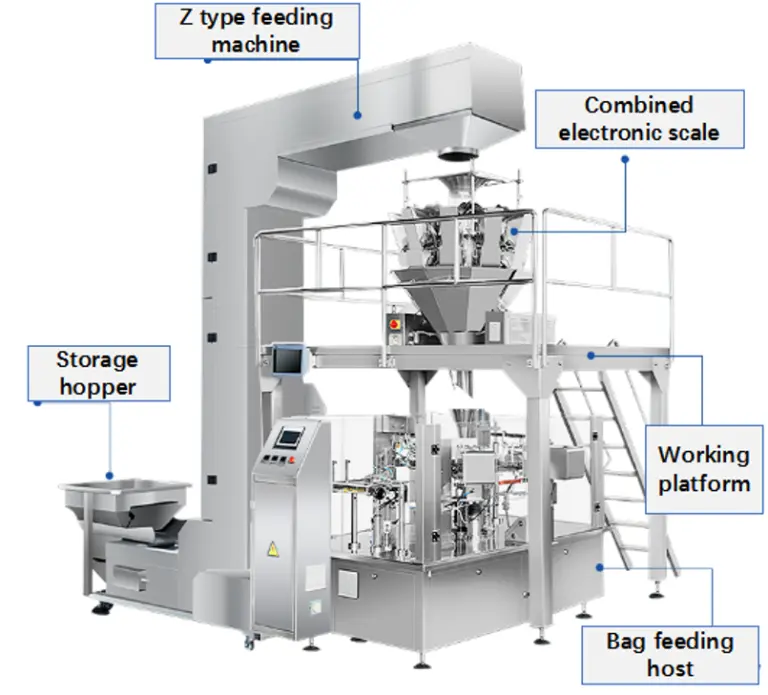

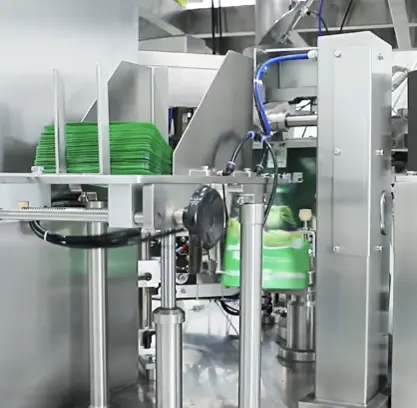

◆ Pouch packing machine design - structure

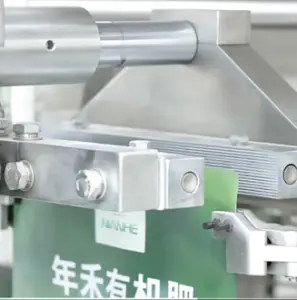

◆ Pouch packing machine design - details

-

Eight-station bag-feeding overall structure

-

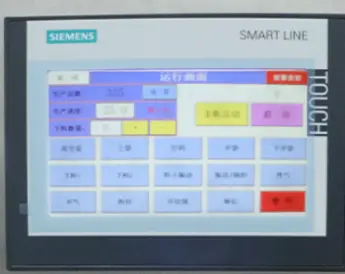

Control panel

-

Bag storage

-

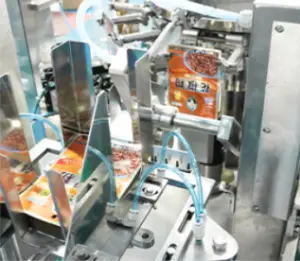

Bag feeding

-

Filling device

-

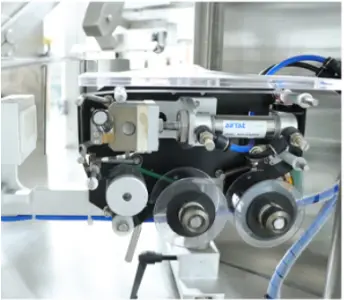

Coding machine

-

Coding machine

Hot-sealing device -

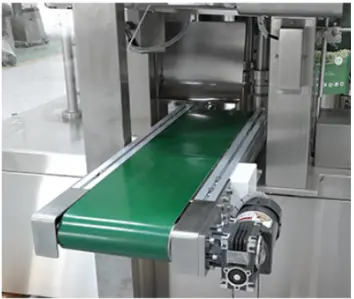

Finished Conveyor Belt

◆ Zipper premade pouch packing machine applicable scope

This zipper premade pouch packing machine has a wide range of applications and can be used for paper-plastic composites, plastic-plastic composites, aluminum-plastic composites, PE composites, etc. The loss of packaging materials is low. It uses prefabricated packaging bags with perfect patterns and good sealing quality, thereby improving the product grade;With different feeding devices, this zipper premade pouch packing machine can realize the packaging of many different forms of materials:

1.Liquids: detergent, wine, soy sauce, vinegar, fruit juice, beverages, tomato paste, jam, chili sauce, bean paste.

2.Blocks: peanuts, jujubes, potato chips, crispy rice, nuts, candy, chewing gum, pistachios, melon seeds, nuts, pet food, etc.

3.Granules: condiments, additives, crystalline seeds, seeds, granulated sugar, soft white sugar, chicken essence, grains, agricultural products.

4.Powder: flour, seasoning, milk powder, glucose, chemical seasoning, pesticide, fertilizer.

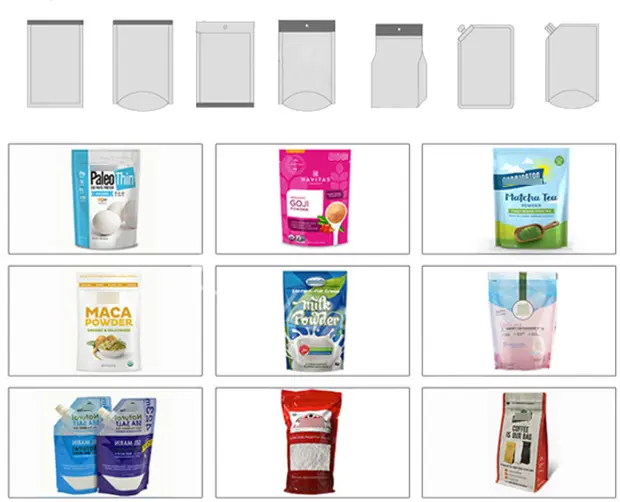

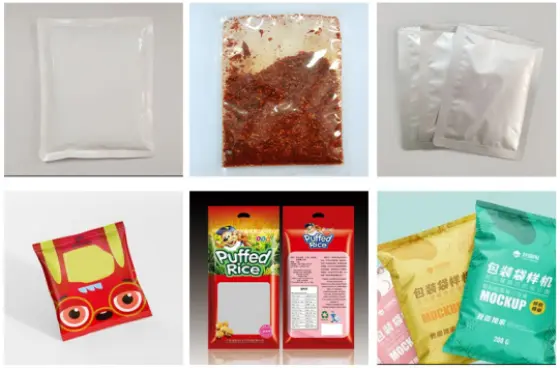

◆ Optional bag type

The zipper premade pouch packing machine has a variety of packaging bag styles that can be customized to meet your packaging needs for different products and different bag types.

◆ Packaging sample display

◆ Packing and shipping

◆ Multipurpose use of zipper pouch packaging machine

This pouch machine with zipper can also be used for multiple purposes. It only needs to be equipped with different metering and feeding devices according to different materials to realize automatic bag packaging of granules, powder, lumps, liquids, soft cans, toys, hardware and other products. And the zipper pouch packing machine price is from 33000 usd to 38000 usd accoding to configuration required by customer.

◆ Contact us

The automatic zipper pouch packing machine is not only efficient and labor-saving, but also has a wider selection of packaging bags, which makes it more and more popular among enterprises. Therefore, many enterprises have chosen this type customized zipper pouch packaging machine in the process of upgrading. If you also want to improve your packaging efficiency and save costs, this fully automatic pouch packing machine is a good choice for you. If you need to replace or purchase a packing machine, please contact us.

◆ More related knowledges

Zipper pouch bag packing machine features

1.Easy to operate;

Adopt PLC control, equipped with touch screen man-machine interface control system, easy to operate.

2.Frequency conversion speed regulation;

This automatic stand up pouch packing machine uses a frequency conversion speed regulating device, and the speed can be adjusted freely within the specified range.

3.Automatic detection function,

If the bag is not opened or the bag is incomplete, it will not be filled and heat-sealed, and the bag can be reused without wasting materials, saving production costs for users.

4.Safety device, when the working air pressure is abnormal or the heating pipe fails, it will alarm and prompt.

5.The bag storage device can store more bags, has lower requirements on bag quality, and has a high bag opening and filling rate.

6.The adjustment of the bag width is controlled by a motor.

Press and hold the control button to adjust the width of each group of clamps at the same time, which is convenient to operate and saves time.

The zipper bag opening mechanism is specially designed for the characteristics of the zipper bag opening to avoid deformation or damage of the bag mouth.

Low packaging material loss.

This automatic pouch packing machine uses prefabricated packaging bags with perfect patterns and good sealing quality, which improves the product grade.

Comply with the hygienic standards of the food processing industry.

The automatic pouch packing machine parts in contact with materials or packaging bags are processed with stainless steel or other materials that meet food hygiene requirements to ensure food hygiene and safety.

Wide range of packaging,

By choosing different metering devices, this automatic zipper pouch packing machine can be applied to the packaging of liquids, sauces, granules, powders, irregular lumps and other materials.

The packaging bag material has a wide range of applications.

This zipper pouch packing machine can be applied to prefabricated bags and paper bags made of multi-layer composite film, silica, aluminum foil, single-layer PE, PP and other materials.

Working process of zipper pouch packing machine

1. Loading bag: the bag is sent to the machine folder by taking it up and down, and there will be an early warning when there is no bag, so as to reduce the employment and labor intensity;

2. Print production date: Ribbon detection, when the ribbon is used up, it will stop and alarm, and the touch screen will display to ensure that the packaging bags are coded normally;

3. Open the bag: open the bag for detection, if the bag is not opened, the material will not drop, ensuring that the material will not be lost;

4. Filling material: testing, if the material is not filled into the bag, the heat seal will not be sealed, ensuring that the bag will not be wasted;

5. Heat sealing: alarm when the temperature is abnormal to ensure the sealing quality;

6. Cooling, shaping and discharging: ensure the sealing is beautiful.

Possible failures of the bag packaging machine

Although the vacuum fully automatic premade pouch packaging machine has outstanding advantages and reasonable operation can bring many benefits to the enterprise, it is inevitable that some failures will occur during the actual operation. In addition to contacting the manufacturer as soon as possible when encountering a problem, bookmark these tips can help you do self-check and solve the problem more quickly and efficiently.

Fault 1: The film material is easy to shift and cannot be fed normally when the automatic premade pouch packaging machine is working.

The technician said that if the film material is offset in the equipment, you can adjust the position of the film roll and the tension balance bar, if it is still invalid, the problem can be solved by adjusting the angle of the upper triangular plate. In addition, if the upper film material deviates from the clamping chain, the upper triangular plate can be adjusted clockwise; the lower film material deviates from the clamping chain, the upper triangle can be adjusted counterclockwise.

Fault 2: The heater heats up slowly or cannot rise to a higher temperature.

Since the main power line of the heater passes through a magnetic switch and then to the electric heating tube, if the temperature of the heater is slow or cannot be raised to a higher temperature, first check whether the contacts of the magnetic switch are normal.

•Generally speaking, if the line does not pass through any of the phases, the above phenomenon will appear;

•If the magnetic switch is normal, you can check the ammeter again to see if the ohm value of each phase is the same as that of the machine;

•If all phases are connected but the circuit or electric heating tube is still abnormal, the heater needs to be replaced.

Fault 3: The vacuum degree of the packaged product is low.

The vacuum degree of the product mainly depends on the vacuum pump. When this kind of problem occurs, the user should check whether the vacuum pump oil is contaminated. If it is polluted, the vacuum pump oil needs to be replaced.

Fault 4: The seal is uneven or not sealed.

The cause of this failure is related to whether the heating time has been adjusted properly and whether there are impurities on the heating isolation cloth. The user needs to adjust the heating time and heating temperature. If there is something attached to the heating isolation cloth, it should be cleaned and replaced in time to prevent it from affecting the normal work of automatic premade pouch packaging machine.

In addition to knowing the common faults and the corresponding solutions of the automatic premade pouch packaging machine, the technical users in the workshop also need to pay attention to the daily maintenance work after the fully automatic pouch packing machine is used, so as to ensure that the machine can be used normal next time and prolong the service life of the device.

How to choose a high-efficiency pouch packing machine?

ØHow to choose a high-efficiency pouch packing machine?

In the production of bagged food, a multifunctional and efficient () is the key to determine the effect of food packaging. In a sense, the automatic pouch packing machine is its key foundation. In the past industry, bagged food was mostly filled manually and sealed automatically, which was a semi-automatic process. Today's packing machines can realize a series of packaging processes such as feeding, bag making, filling, sealing, coding, and bag cutting, which not only saves time but also improves work efficiency. However, there are many kinds of automatic pouch packing machine on the market, and the quality and packaging effect are of course also different. So how to choose a multi-functional and high-efficiency pouch packing machine among so many automatic packaging machines?

1. Choose pouch packing machine according to your own packaging requirements;

Choose according to your material type, production scale, packaging speed, single bag packaging weight and packaging form;

2. Consider the pouch packing machine spare parts;

In order to ensure the normal use of the fully automatic pouch packing machine, it is best to equip a certain number of pouch packing machine spare parts when purchasing the equipment. During the operation of the equipment, the loss rate of many parts is very high. Once a failure occurs, it must be replaced in time to avoid affecting production. Choosing a supplier that can provide a wealth of pouch packing machine spare parts can make you feel more at ease.

3. Choose the right automatic pouch packing machine supplier;

In many cases, a big brand does not mean that it is the best choice. You should choose a supplier with excellent quality and after-sales service.

4. Don’t only look at the pouch packing machine cost;

When users purchase automatic pouch packing machine, they are more concerned about the pouch packing machine cost, but they must not only pay attention to the low price and ignore the quality. It will be a big hidden danger for the later production, and it will even bring higher maintenance costs, which is not worth the candle.

5. Consider the power of the stand up pouch packing machine;

The power of the automatic pouch packing machine determines whether the machine saves electricity, and packaging with large power consumption will increase new production costs. This is where many people overlook.

6. High cost performance is the first principle.

Choose a pouch packing machine automatic model with mature technology and stable quality to make the packaging faster and more stable, with low energy consumption, low manual work, and low scrap rate. The fully automatic pouch packing machine is a consumable machine. If you buy a low-quality machine, the packaging film that will be wasted in daily production in the future will also be a huge cost.

+86 19112905173

+86 19112905173