Granule packing machine

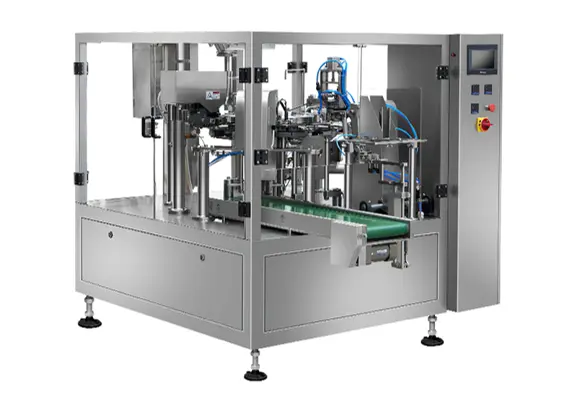

◆Automatic pouch packing machine description

The automatic granule packing machine is widely used in the packaging of food (such as millet, nuts, candy, coffee, etc.), mainly for sub-packaging, quantification and packaging of food. In the process, the manual operation is reduced, the packaging is fully automated, the measurement is accurate, and the packaging is good. The material is all made of SS304 food-grade stainless steel. Customers from various companies can rest assured to use the granule pouch packing machine.

•Fully automatic, less noise, high precision, fast speed;

•Using color touchscreen and reliable dual-axis high-precision output PLC control;

•Bag making, measuring, filling, sealing, coding, and bag cutting are completed at one time.

The granule weighing & packing machine is easy operation and easy understanding, can withstand repeated use and is not easy to break, the built-in components are durable and have a long life. it is loved by relevant factories and staff.

◆Product parameters

This automatic granule packing machine has three models: YS-420, YS-520, and YS-720, which can pack products of different capacities and meet the different needs of users. The places marked in red are the main differences of the three models.

| Model | YS-420 |

|---|---|

| Packing speed | 5-60 bags/min |

| Film width | 420mm |

| Measuring range | MAX.: 1500ml |

| Bag size | (L)80-300mm (W)60-200mm |

| Film thickness | 0.04-0.08mm |

| Film pulling method | Double belt pull film |

| Barometric pressure | 0.65mpa |

| Air consumption | 0.4m3/min |

| Power type | 2.2KW 220V 50HZ |

| Dimensions | (L)1450mm (W)1020mm (H)1350mm |

| Total Weight | 450kg |

| Model | YS-520 |

|---|---|

| Packing speed | 5-50 bags/min |

| Film width | 520mm |

| Measuring range | MAX.: 3000ml |

| Bag size | (L)80-400mm (W)80-250mm |

| Film thickness | 0.04-0.08mm |

| Film pulling method | Double belt pull film |

| Barometric pressure | 0.65mpa |

| Air consumption | 0.4m3/min |

| Power type | 4KW 220V 50HZ |

| Dimensions | (L)1450mm (W)1120mm (H)1650mm |

| Total Weight | 600kg |

| Model | YS-720 |

|---|---|

| Packing speed | 5-40 bags/min |

| Film width | 720mm |

| Measuring range | MAX.: 7500ml |

| Bag size | (L)100-500mm (W)200-250mm |

| Film thickness | 0.04-0.08mm |

| Film pulling method | Double belt pull film |

| Barometric pressure | 0.65mpa |

| Air consumption | 0.65m3/min |

| Power type | 6KW 220V 50HZ |

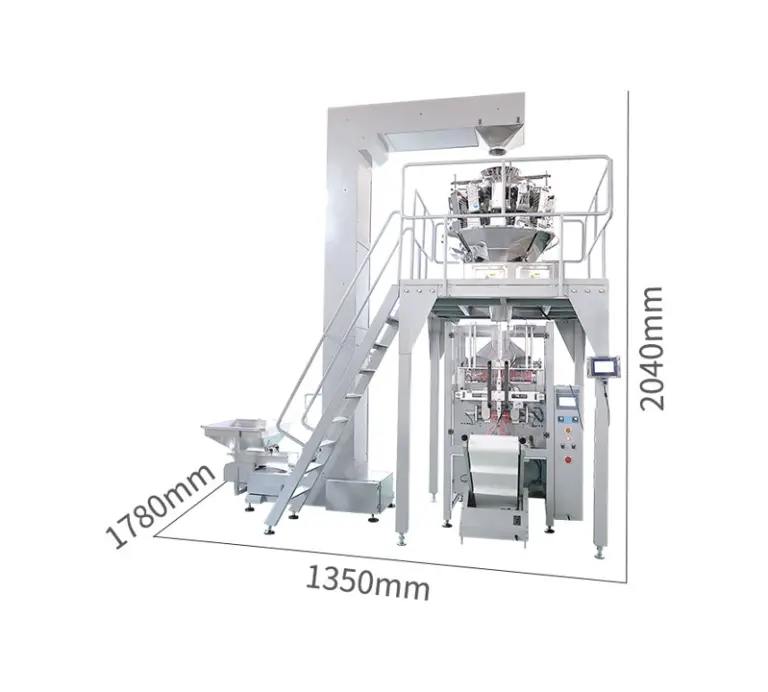

| Dimensions | (L)1780mm (W)1350mm (H)2040mm |

| Total Weight | 900kg |

◆ Product Features

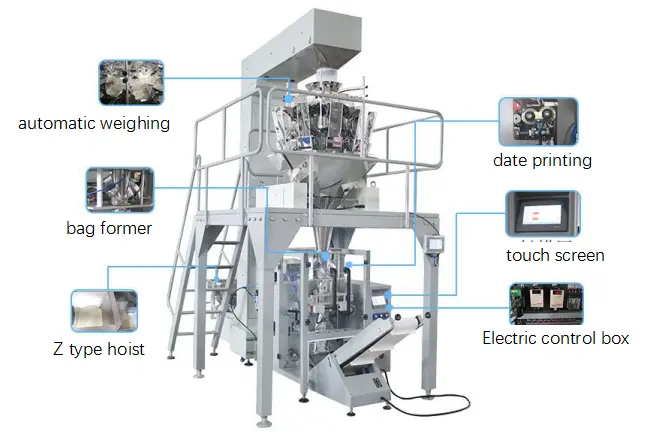

1.Multi-head(10) combined weigher, improve metering speed and accuracy.

2.Touch screen, easy operation and multiple language for choice.

3.Imported PLC system, machine performance is stable and easy for parameters adjusting.

4.With a memory function for parameters storage. Easy to change packing product.

5.Separate PID temperature controller, suitable for various packing materials.

6.Multi-union roll film pulling system make film running more smooth.

7.Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8.Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

9.Machine automatically finish the process of filling, metering, bag forming, date printing, sealing and packing.

10.Low loss, labor saving, easy for operation and maintenance.

◆ Packaging range

◆ Product details

-

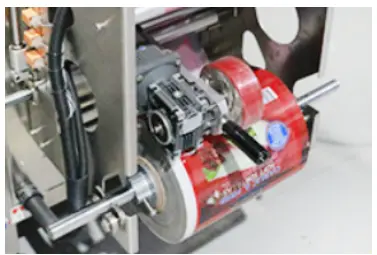

Bag former

The metal panels on both sides are folded and rolled into a bag, which is strong and beautiful. -

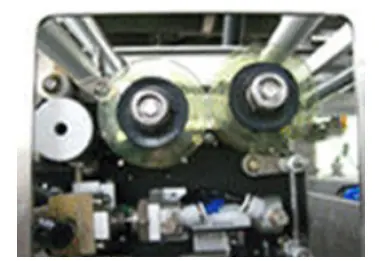

Vertical seal

Independent PID temperature control, vertical sealing is suitable for multi-style bags, more stable packaging molding, and guaranteed airtightness -

Horizontal seal

Constant temperature heat sealing cutter, sealing the front and rear ends of the package, optional gusset

-

Touch screen

It adopts touch screen control in both Chinese and English, controls the parameter adjustment through the intelligent system, and runs by piece counting. Parameter adjustment is more convenient. -

Film release device

The servo motor is used to pull the film, so that the film is more stable and does not run away. The external film release mechanism is used to make the installation of the film more convenient and safer. -

Coding machine

Using imported coding machine, track and print the production date, batch number, etc., the printing speed is fast, the printing area is wide, the printing arrangement is flexible, and the one-key operation is faster and more stable.

◆ Granule packing machine price

The granule packing machine price is much different base on its type and structure, this granule weighing & packing machine model is mainly composed of vertical packaging machine (main machine), 10-head computer combination scale, working platform, Z-type automatic feeding machine, finished product conveyor belt, and vibrating feeding bin, which can be purchased separately, and sure will have different price. We are professional granule packing machine manufacturers, produce and export various pouch packing machine such as automatic liquid pouch packing machine, ketchup pouch packing machine, tablet pouch packing machine etc. Welcome to contact us for the exactly details.

◆ Granule packing machine expands knowledge

What preparations should be done before using the granule packing machine?

1. Clean up the dirt, sundries and other items on the machine, and clean and disinfect all parts in contact with food.

2. Check whether the screws are loose during transportation. Turn the belt one circle by hand to check whether the granule pouch packing machine is stuck and cannot rotate. If so, find out the reason and eliminate it.

3. Add lubricating oil (36# oil) to the moving parts such as the horizontal sealing guide post, the cam, and the feeding clutch. Check whether the reduction box is short of oil, if it is lower than the center line of the oil tank, please add 36# engine oil.

4. Turn on the power and close the leakage switch in the electric control box.

5. Set the required temperature of the vertical sealing and horizontal sealing molds, and let the temperature on the temperature control table rise to the required temperature of the packaging material.

Can granules with poor fluidity be used in a granule pouch packing machine?

The granule pouch packing machine is mainly used for the following granular materials with good fluidity: pesticides, veterinary drugs, seeds, medicine, feed, coffee, fruit extract, desiccant, salt, monosodium glutamate, soup, tea, washing powder, salt, dry seasoning, sugar, etc. and free-flowing granule products.

If you want to pack particles with poor fluidity, you can use a special packaging machine.

How to maintain the granule weighing & packing machine?

1. After the granule weighing & packing machine stops working, the metering part should be cleaned in time. If sugar, salt, powder, liquid, etc. are packed, the feeding tray and turntable should be cleaned every day to prevent corrosion.

2. The materials scattered on the tray should be cleaned up in time to keep the parts clean.

3. The photoelectric tracking light-emitting head, that is, the electric eye, should also be cleaned regularly to ensure that the cursor tracking error is small.

4. The body of the heat sealing machine should be cleaned frequently to ensure clear seal texture.

5. Regularly clean the dust in the electrical cabinet to prevent failures such as poor contact of the granule packing machine.

Precautions for using automatic granule packing machine

1. After the automatic granule packing machine is installed, fix it with expansion screws, connect the power line and gas pipeline reliably, and test it with no load. The granule weighing & packing machine can be used only after it is correct.

2. Regularly add lubricating oil to the reducer, bearing and other parts that need to be lubricated. Regularly check whether the fasteners of the equipment are loose.

3. The pressure of the gas source should be stable, and the gas should be clean and dry. And the user's air source must have an oil mist filter device to ensure that the compressed air contains oil mist to lubricate the cylinder and ensure the service life of the pneumatic components.

4. The granule pouch packing machine should be used indoors, and electrical components, motors, etc. should not be splashed with water. Cylinders, buttons, sensors, etc. cannot be artificially added with dust, particles and other dirt to avoid machine damage.

5. The operating voltage of the granule pouch packing machine is 380V and 220V, and the operator must be trained before operating.

Common faults and solutions of automatic granule weighing & packing machine

•Fault description:

When the granule packing machine is running, there may be a large deviation in the bag cutting position, the gap between the color marks is too large, the color mark positioning is poor, and the photoelectric tracking compensation is out of control.

Solution:

In this case, you can first readjust the position of the photoelectric switch. If not, then clean the forming machine, insert the packaging material into the guide plate, adjust the position of the guide plate so that the light spot coincides with the color mark.

•Fault description:

During the granule packing machine operation, if the starting capacitor is damaged, the paper feeding motor may be stuck, or the motor may be damaged and rotate uncontrollably. These are some common failures.

Solution:

First check whether the paper feed control lever is stuck, whether the starting capacitor is damaged, and whether the fuse is faulty, and then replace it according to the inspection results.

•Fault description:

The small automatic pouch packing machine is not sealed or the seal is not tight. This will not only waste materials, but also cause easy distribution and pollution of automatic particle packaging machine equipment and working environment because the materials are all powdery.

Solution:

Check whether the packaging material complies with the relevant regulations, take out the inferior packaging materials and no longer use them, and then try to adjust the sealing pressure and increase the heat sealing temperature. In this case, the problem is solved.

•Fault description:

The pouch packing machine automatic does not pull the bag, and the bag pulling motor fails to work. Most of the reasons for this failure are line problems. The bag switch is broken, the controller is faulty, the stepper motor driver is faulty.

Solution:

Check whether the proximity switch of the bag making machine, the controller, and the stepper motor are damaged, and replace the damaged parts.

•Fault description:

During the operation of the small automatic pouch packing machine, the packaging material is often torn.

Solution:

Check the motor circuit and observe whether the switch is damaged.

The above are several common faults and solutions of the granule weighing & packing machine. Of course, in actual use, the possible faults are far more than these. When we encounter failures, we must first calm down, locate the failure, and then check whether the relevant modules are damaged, so as to greatly improve the efficiency of troubleshooting.

+86 19112905173

+86 19112905173